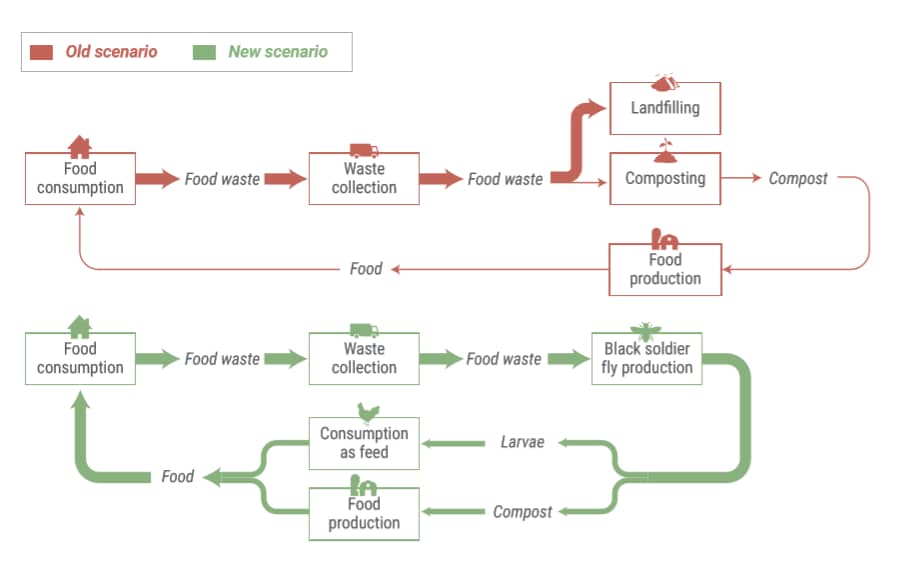

When it comes to the role of insect protein in the transition to a sustainable food system, the first thing that comes to mind for most is the growing trend of pan-fried crickets and dry-roasted mealworms as part of our diets. But for those squeamish about eating bugs, insects can serve another vital function: as consumers of our waste, and as feed for livestock.

This isn’t speculation, but something that is happening here and now. A prime example is Dutch insect ingredient company Protix, which has just unveiled a €35 million commercial-scale production facility in the town of Bergen op Zoom that upcycles food waste into sustainable protein for a range of animals, including for fish, chicken, and pets. Protix feeds the food waste to black soldier fly larvae, which eat up to twice their own body weight every day, are easy to farm, and serve as an excellent source of protein.

Food waste into valuable body mass

According to Protix, insects can turn food waste into valuable body mass very fast and with a low impact on resources: one tonne of insect can be grown in six days using a land area of 20 square meters. The company argues that, with a third of all fish used as animal feed and land-intensive soy used to feed cattle, insect larvae are a sustainable alternative feedstock. Protix is also supplying feed to the Norwegian salmon industry, and can use byproducts of insect production in fertilizer and textiles.

The nursery in Bergen op Zoom offers a “future proof, circular food chain”, according to Protix Founder and CEO Kees Aarts. “The opening of the new production facility in Bergen op Zoom is not just for Protix, but for the whole insect industry, a real transformation,” he says. “This nursery is unique in the Netherlands, Europe, and the world.”

Growth across Europe and North America

Protix isn’t the only company ramping up insect-based feed to a commercial scale. Another example is French firm InnovaFeed, which is moving beyond its first pilot insect production site in Gouzeaucourt to begin construction in April on a production site ten times larger in Nesle in Northern France, where it will feed waste from an adjacent starch facility owned by Tereos to insect larvae, which in turn will feed fish. Through this industrial symbiosis, the operation will avoid 25,000 tons of CO2 per year. Commissioning is slated for the last quarter of 2019, with the two companies planning to deploy a similar model at more sites across France and internationally from 2020-2022.

This approach is also taking off across the Atlantic in North America, following efforts to change regulations to allow insect feed to be used for livestock. EnviroFlight, founded in Ohio in 2010, today sell larvae for livestock, but had to start out selling specialty feed at a premium for backyard chickens and exotic pets before regulations changed. Canada-based Enterra was one of the companies leading the lobbying efforts for change, and is now building three new insect factories in Canada and the US at a cost of roughly $30 million each.

US city turns to insects to kickstart circular economy

The US city of Charlotte is looking to black soldier fly larvae as a key part of its transition to a circular economy. One of five business cases developed by Metabolic for Envision Charlotte as part of the Circular Charlotte plan projected that if 50,000 tons of the city’s food waste is diverted to insect larvae production, this would reduce the amount of food waste going to landfill by 5.3% and save the municipality $1.65 million in tipping fees, and prevent nearly 90,000 tons of CO2e emissions per year through diversion from landfill (where the food waste would have emitted methane).

An additional 7,000 tons of CO2e would be saved from the 6,800 tons of poultry feed that can be replaced by black soldier fly larvae. The replacement of poultry feed also saves about 41,000 gallons of water per year and 3,200 acres of land. In total, this could generate $200k – $2.5m in profits per year and create 150-250 new jobs in production, as well as an estimated 83 additional jobs created in food waste collection.

The city is putting this into action, with local composting company Crown Town Compost helping to design a pilot facility as part of Charlotte’s circular economy hub, the Innovation Barn. Situated in a glass enclosure, the soldier flies won’t just be helping take care of the city’s food waste – they will also serve as an awareness-raising measure for circular economic solutions.

“Everything is going to be experiential,” Amy Aussieker, executive director of Envision Charlotte, told the Charlotte Observer. “You’ll be able to walk into any part of the building to watch the soldier flies to see how the composting is going. It’s designed to be open to the public.”

For more on circular food waste solutions, reach out to sustainability consultant Andrew McCue at [email protected]