New strategy for raw material management in the Southern Region of Denmark

Striving for sustainability across the entire value chain.

The Region of Southern Denmark commissioned Metabolic to develop a conceptual framework for sustainable raw material management, and to analyze how the extraction and consumption of raw materials can become more circular. The project resulted in two reports: part 1 defines what sustainable raw material management is, on the basis of six principles. Part 2 provides an overview of the region’s material flows and identifies initiatives that can drive the transition towards a more circular and sustainable management of raw materials across the value chain.

- Client: Southern Region of Denmark

- Date: September 2020

Raw materials are the base of every supply chain

Raw material extraction is the first step in most of our supply chains. Raw materials are therefore crucial to our economy, but they are also finite, and their extraction and consumption have significant environmental impacts. Hence, it is crucial that we manage them effectively.

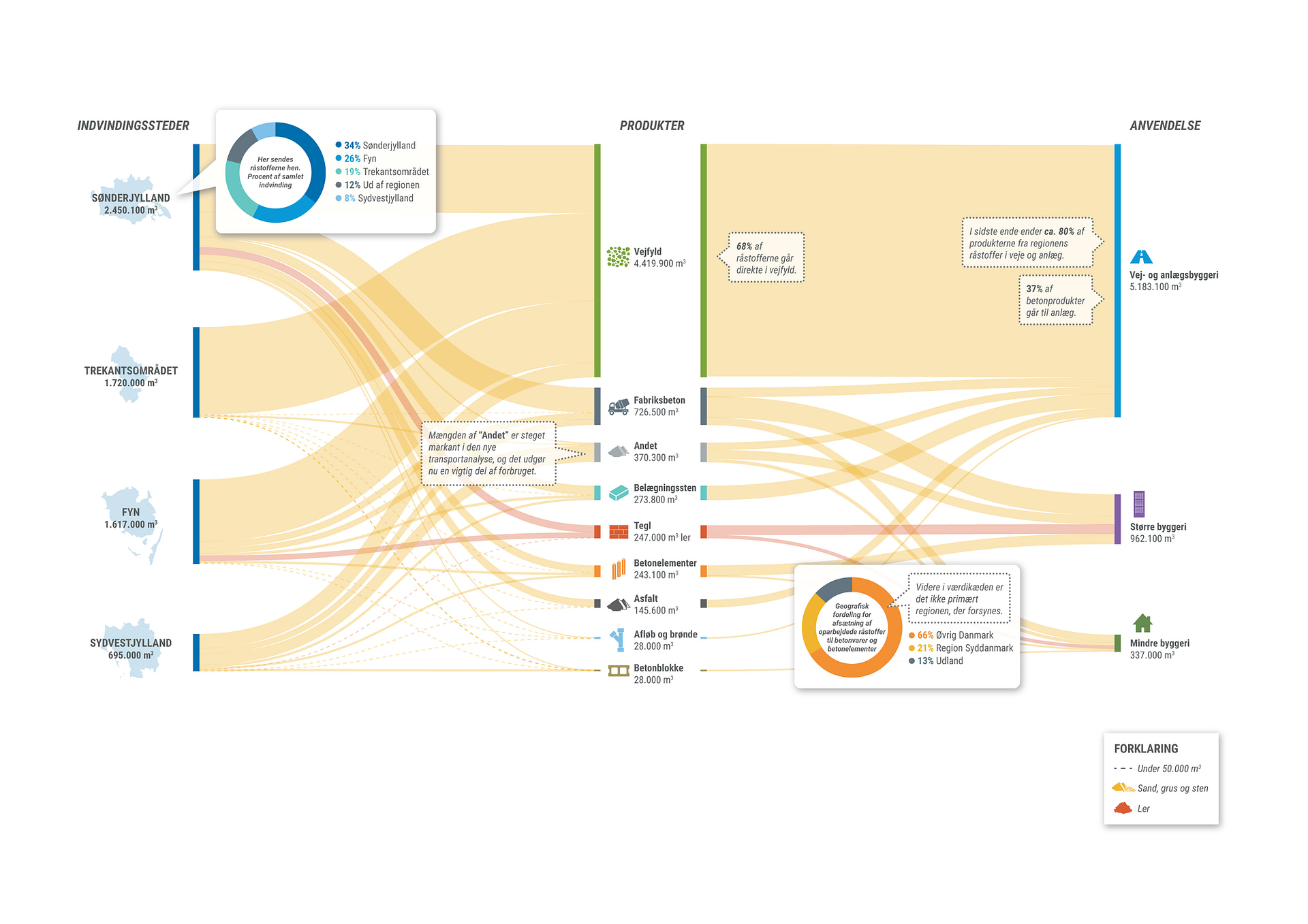

The Region of Southern Denmark extracts 6.4 million cubic meters of raw materials every year. 80% of these are used for road and infrastructure constructions and 20% are used in the building sector. The Region is preparing a new raw materials strategy, which will provide an opportunity to rethink raw material management in line with the UN sustainable development goals. Ahead of this work, Metabolic has helped define what sustainable raw material management means in practice, and how the region can get there.

Understanding and applying sustainable raw material management

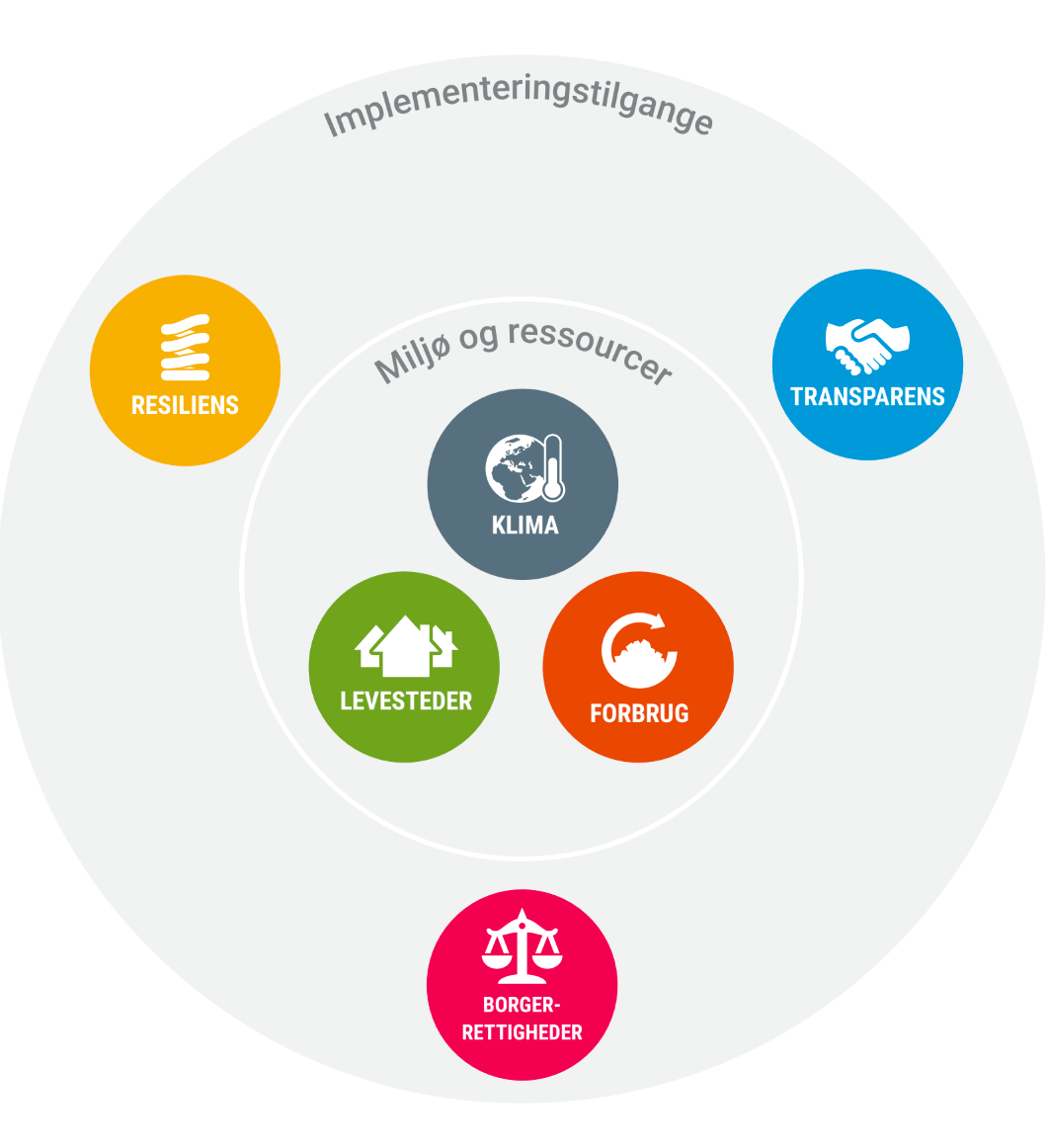

We first developed a conceptual framework for what sustainable raw material management is. The framework contains six actionable principles that can guide the setting of targets, as well as identifying interventions. We also identified how to implement the principles of sustainable raw material management, at the consumption stage, related to the built environment.

The second part of the project consisted of a three-step analysis:

- Supply and consumption: mapping current extraction activities within the Region, as well as the value chain for the raw materials extracted in the region.

- Effects in the value chain: examining which raw material activities in the value chain has the biggest environmental impact.

- Interventions in the value chain: identifying initiatives that are essential for the sustainable management of raw materials in the entire value chain.

Highlighting opportunities to minimize waste and reduce environmental impacts

This project is the first of its kind to include the entire value chain of raw materials, and thus expands the scope of what the region should consider in their planning activities. For example, processing raw materials into construction materials creates thirty times more greenhouse gas impacts than the extraction and transportation phases. By examining the entire supply chain, the region is able to make much more impactful decisions and reduce the consumption of raw materials. There are a number of opportunities to reduce the negative impacts of extraction. For example, around 90 percent of construction waste in Denmark is recycled by crushing the concrete and using it as filling for roads. This reduces the use of new raw materials, but it does not reduce the consumption of new concrete, which has a much higher CO2 footprint.

The consumption of concrete in construction can be reduced through better planning, better design, using square meters more effectively, recycling rather than downcycling existing concrete, and using alternative materials such as wood. The most effective solution is simply to reduce new construction in favor of existing buildings.

Director of Sustainable Cities & Regions

ANY QUESTIONS?

For more information about this project, please get in touch.