Critical metal demand for electric vehicle production

Towards a fair, resilient, and circular transport system that reduces risk and dependency on raw materials.

As countries race to decarbonize their economies, a rapid transition to electric vehicles is underway. But as we design low-carbon passenger transport, we must consider where large shifts may create new dependencies. As demand for personal electric vehicles increases, so too does the demand for specific critical metals used in their production. This report calculates the projected demand of specific metals, analyzes the risks associated with their complex supply chains, and provides recommendations for a future-proof mobility transition.

- Partners: Copper8 and University of Leiden

- Date: October 2019

Escalating critical metal demand in the transition to a clean economy

As a necessary step towards a clean economy, the world is transitioning to a fossil fuel-free future. When it comes to transportation, along with many other countries, the Netherlands is strongly focusing on a steep increase of electric vehicles as one of the primary solutions to the transition to a sustainable mobility system. However, the production of the critical metals needed in electric vehicles, such as nickel, praseodymium, neodymium, cobalt, dysprosium and lithium, would have to scale more than three times in the next 10 years to meet projected global demand.

Our research finds that scaling up production with this intensity poses significant risks. Supply chain constraints, temporary disruptions, unhealthy mining practices, and potential geopolitical conflicts are causes for concern. As we are at the beginning of the transition, this is an opportunity to re-evaluate and develop a fair, resilient and circular transport system.

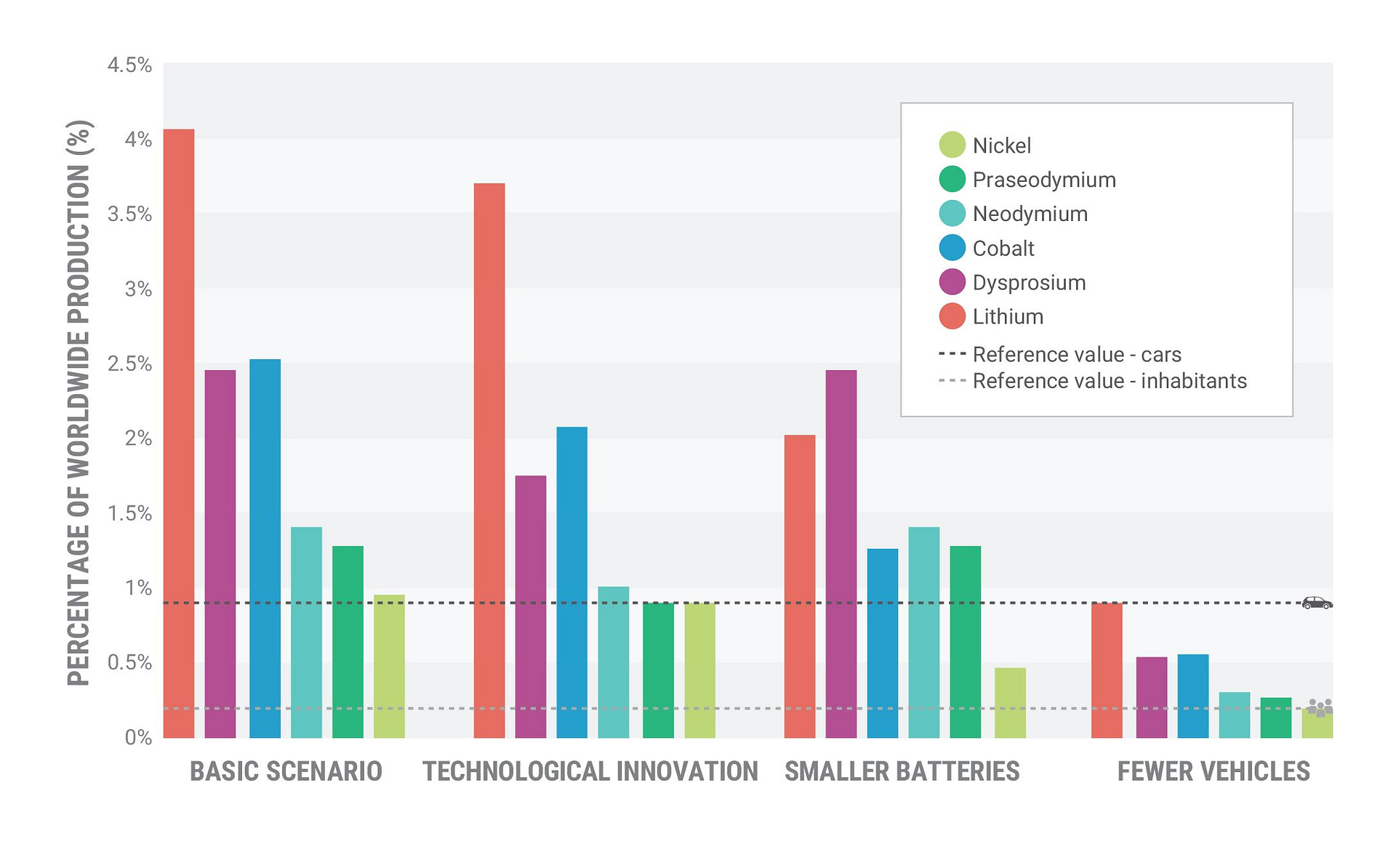

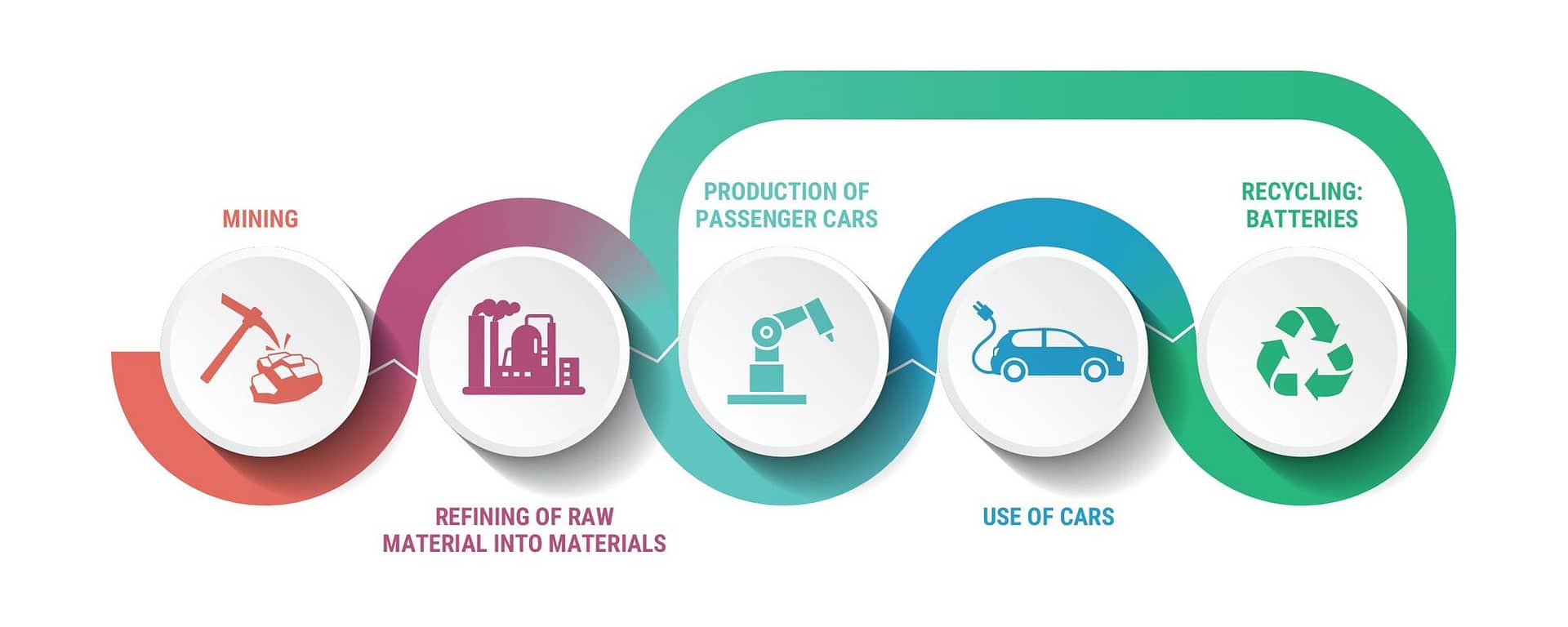

Research and analysis of metal supply chains and projected increases of electric vehicles

We performed in-depth analysis of the supply chains of critical metals for electric vehicles. This was analysed in relation to climate targets as well as electric vehicle targets within the Netherlands as well as other countries, to make predictions on future global critical metal demand as well as observe the feasibility and identifying risks. Our method was to use three scenario solutions: technological innovation, smaller batteries, and fewer cars. These were used as a base to show potential ‘safe zone’ estimates of future metals available for electric vehicles. We provide eight recommendations for both the national level as well as EU level.

The need for a range of mobility solutions for sustainable transport systems

Performing an in-depth analysis of three scenarios, the clear outcome is to integrate multiple mobility solutions that enable a system with fewer cars into the transition to sustainable transport. This involves more effective use of existing vehicles, improved public transport infrastructure and the development of circular design and recycling processes for maximum resource efficiency.

We recommend a range of measures that would help the Netherlands and European Union make the transition to sustainable transport with less dependency on critical metals. Recommendations include new mobility concepts with fewer vehicles, avoidance of infrastructure lock-ins, using smaller batteries for regional solutions, transparency in metal supply chains, increased battery recycling, and development of alternatives to under-pressure metals.

- This report is part of a series on metal demand for a carbon-free economy, following a study on wind turbines and solar panels

- Could a rare metals shortage disrupt the global renewable energy transition?

- COP24: Circular economy the missing link in global climate plan

“Working towards a future with fewer vehicles, we need to redirect finances from the development of additional road infrastructure to more efficient use of our infrastructure and vehicles.”

Sybren Bosch, Copper8 consultant

Director of Product – Metabolic Software

ANY QUESTIONS?

For more information about this project, please get in touch.