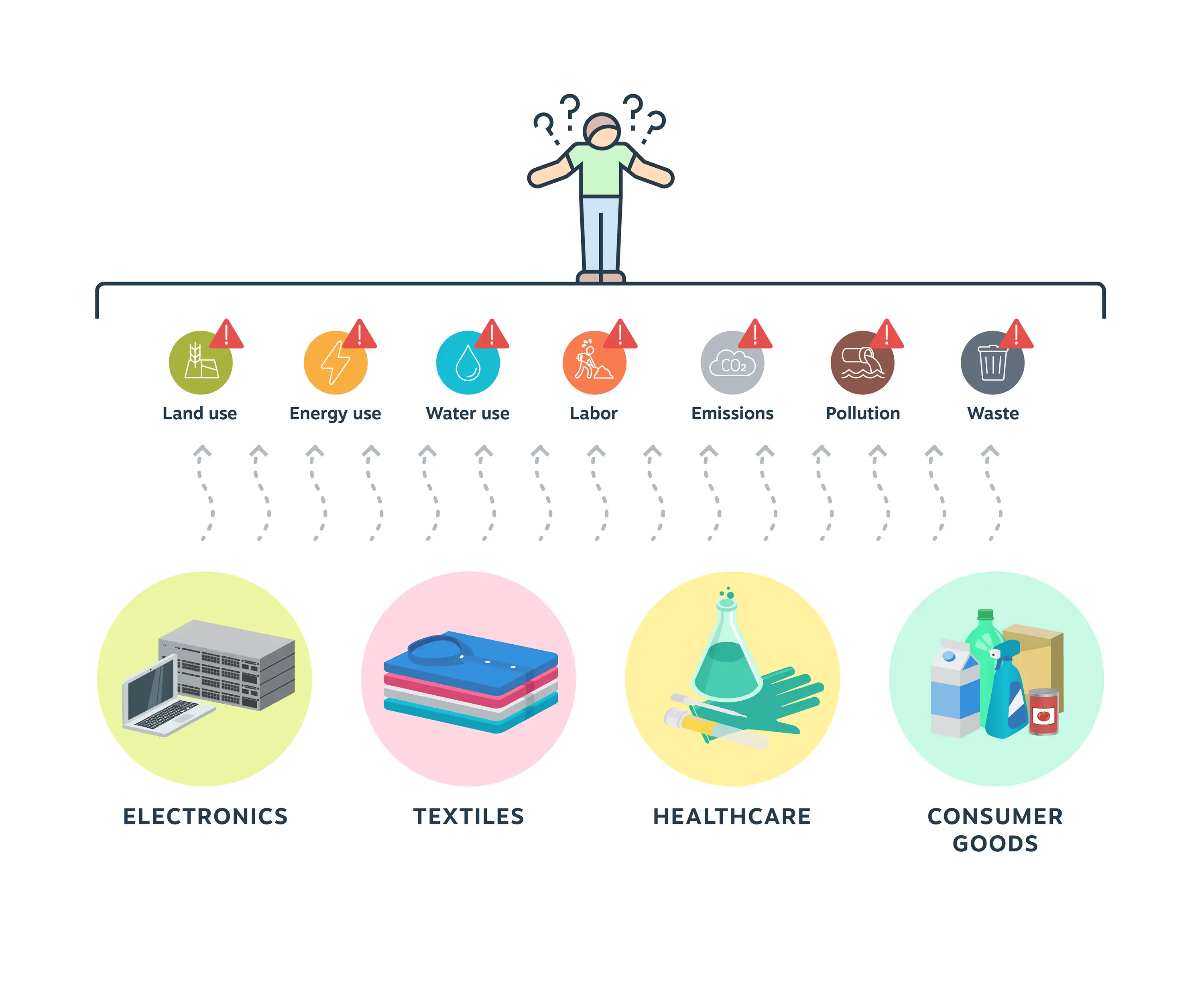

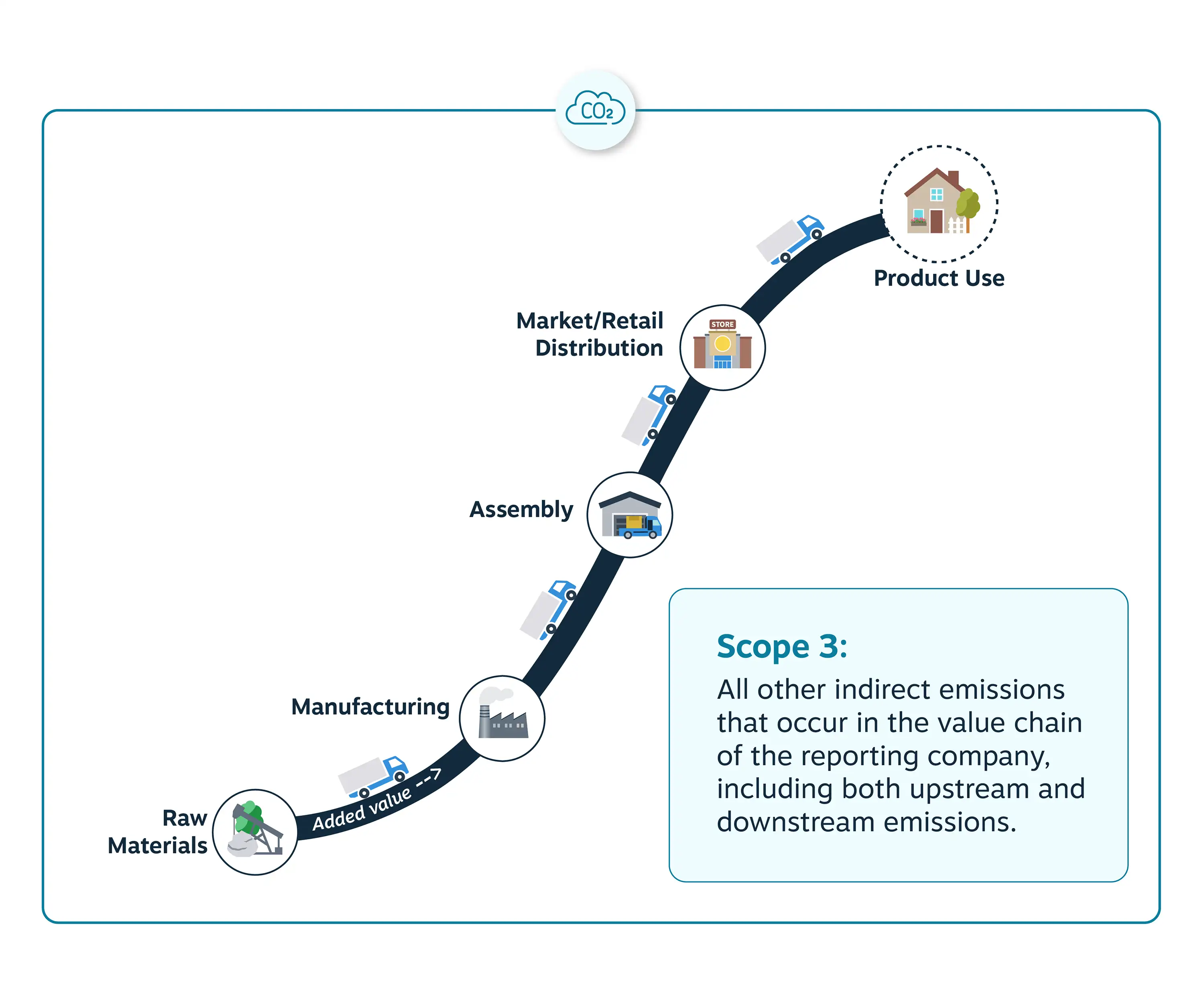

Companies are under increasing pressure to measure and report these impacts, even if outside their direct control.

This includes coordinating sustainability efforts with suppliers and even assessing what happens once the time comes to dispose of a product.

(More on why that isn’t the end of the story is coming up.)

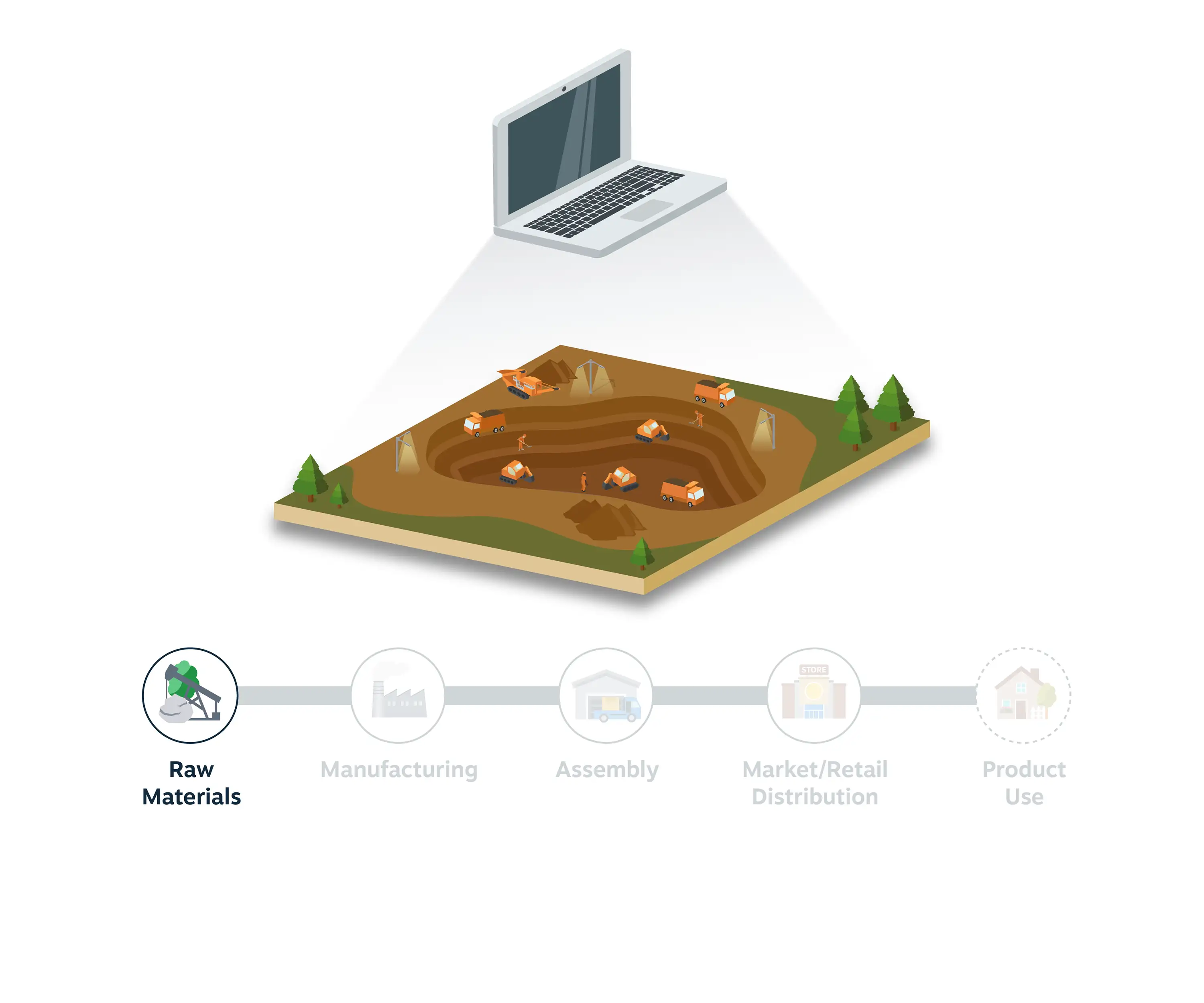

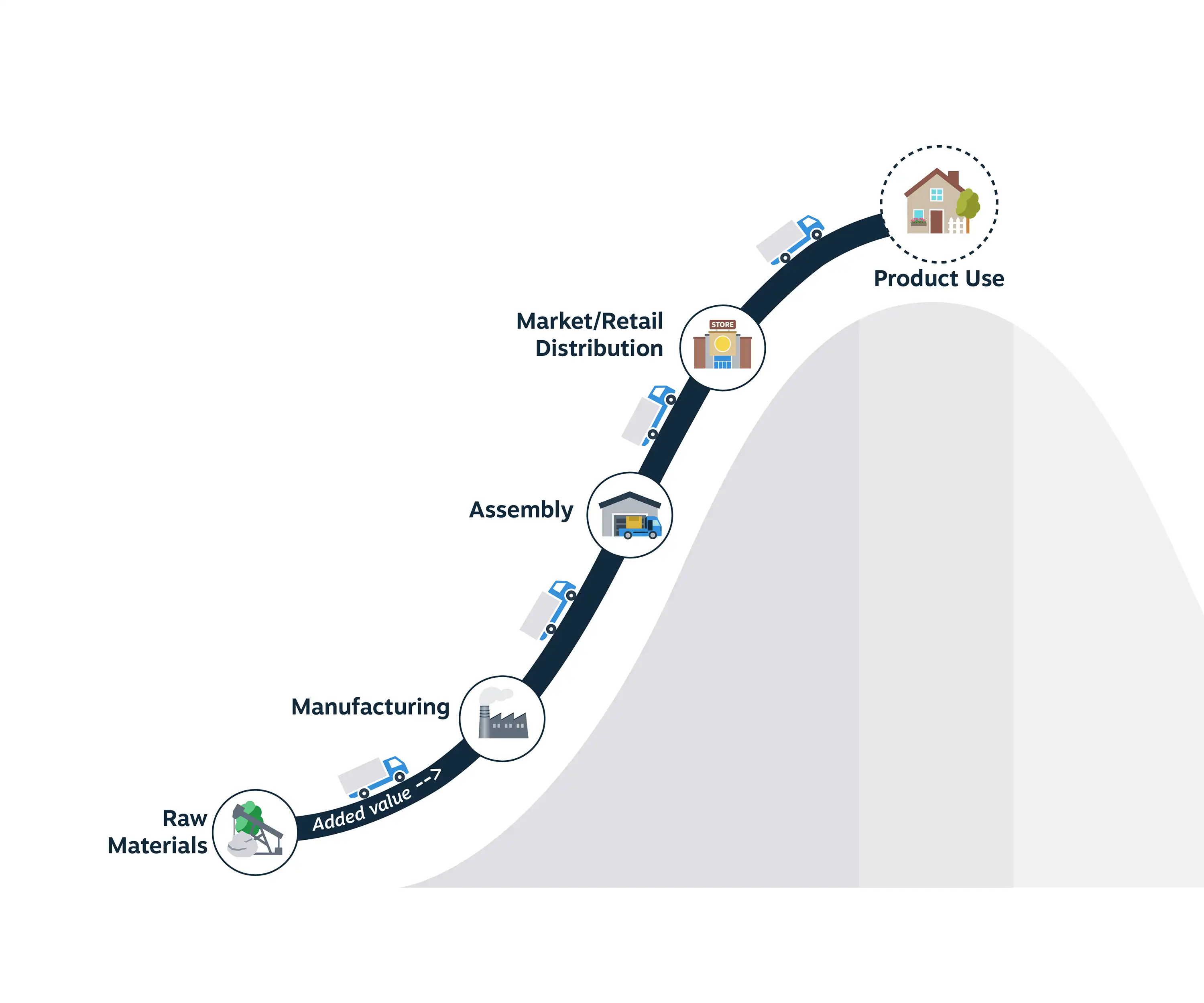

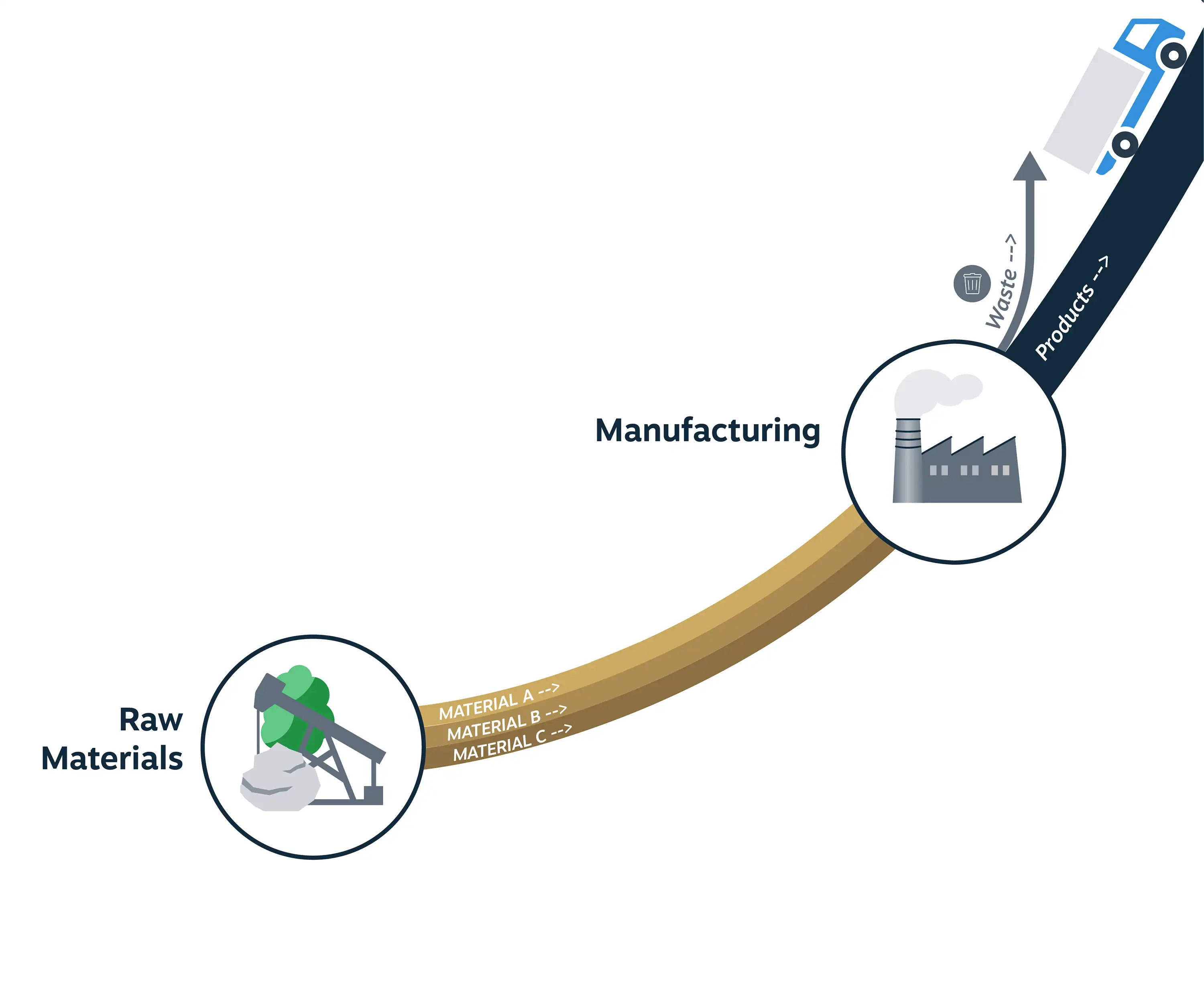

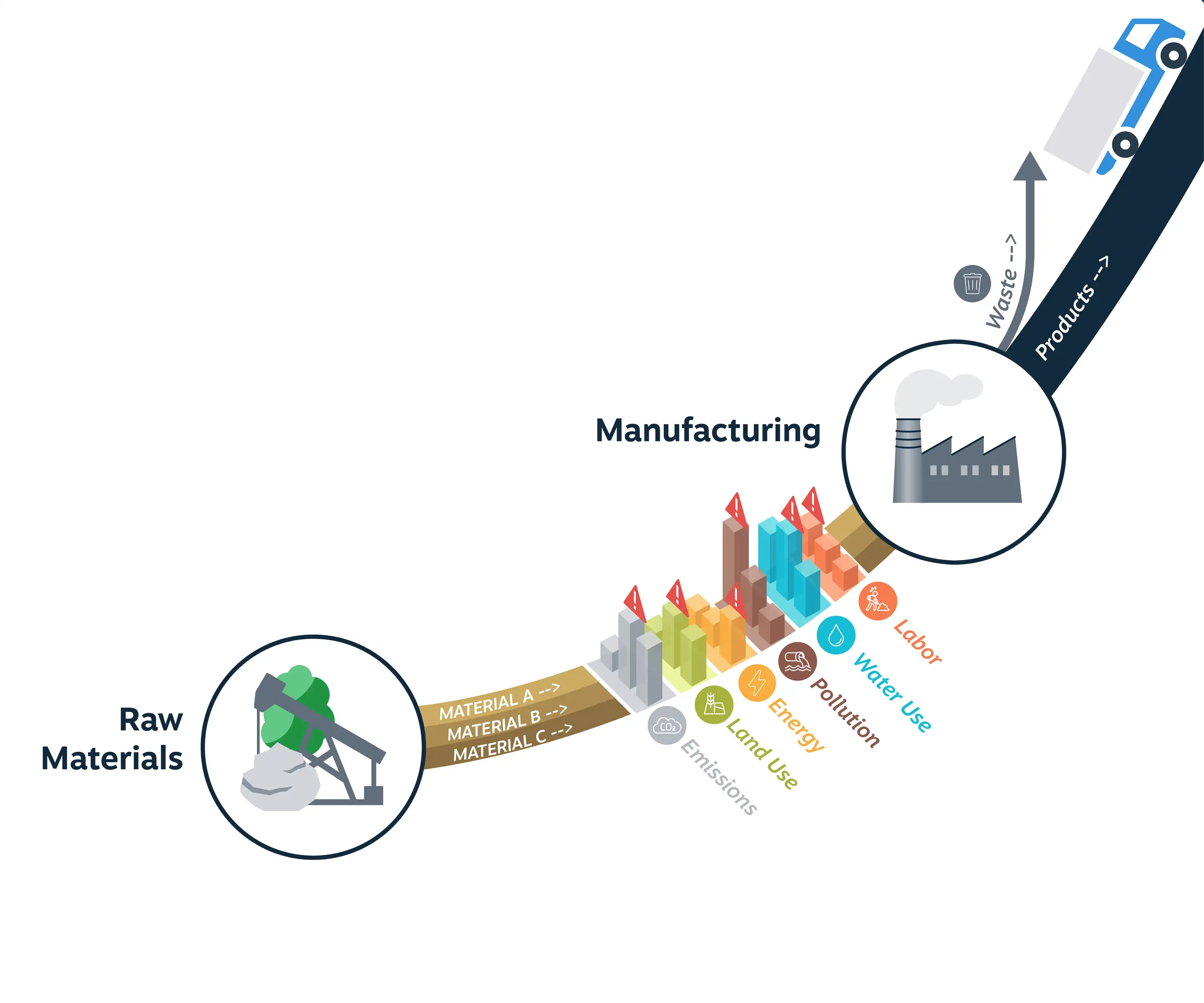

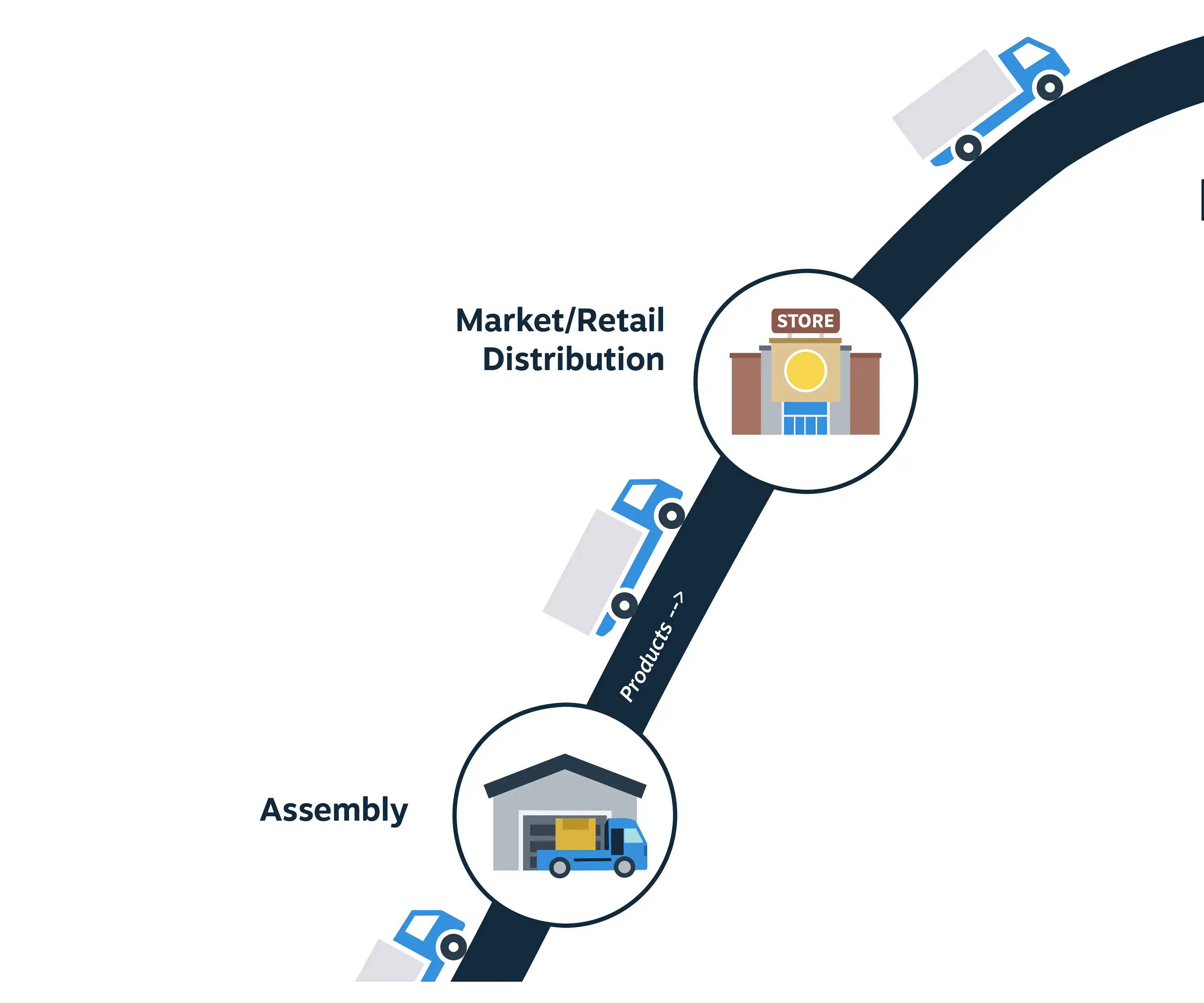

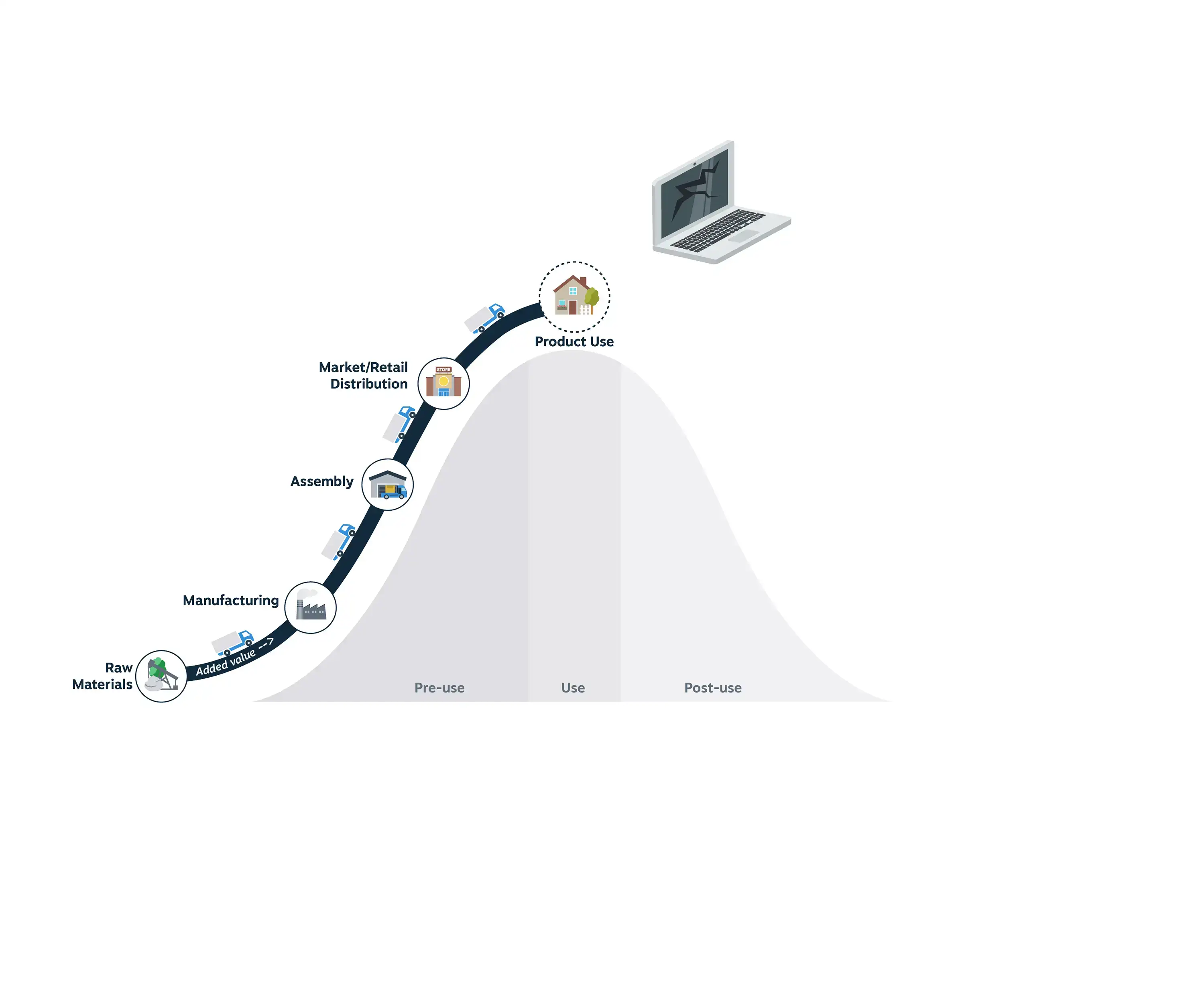

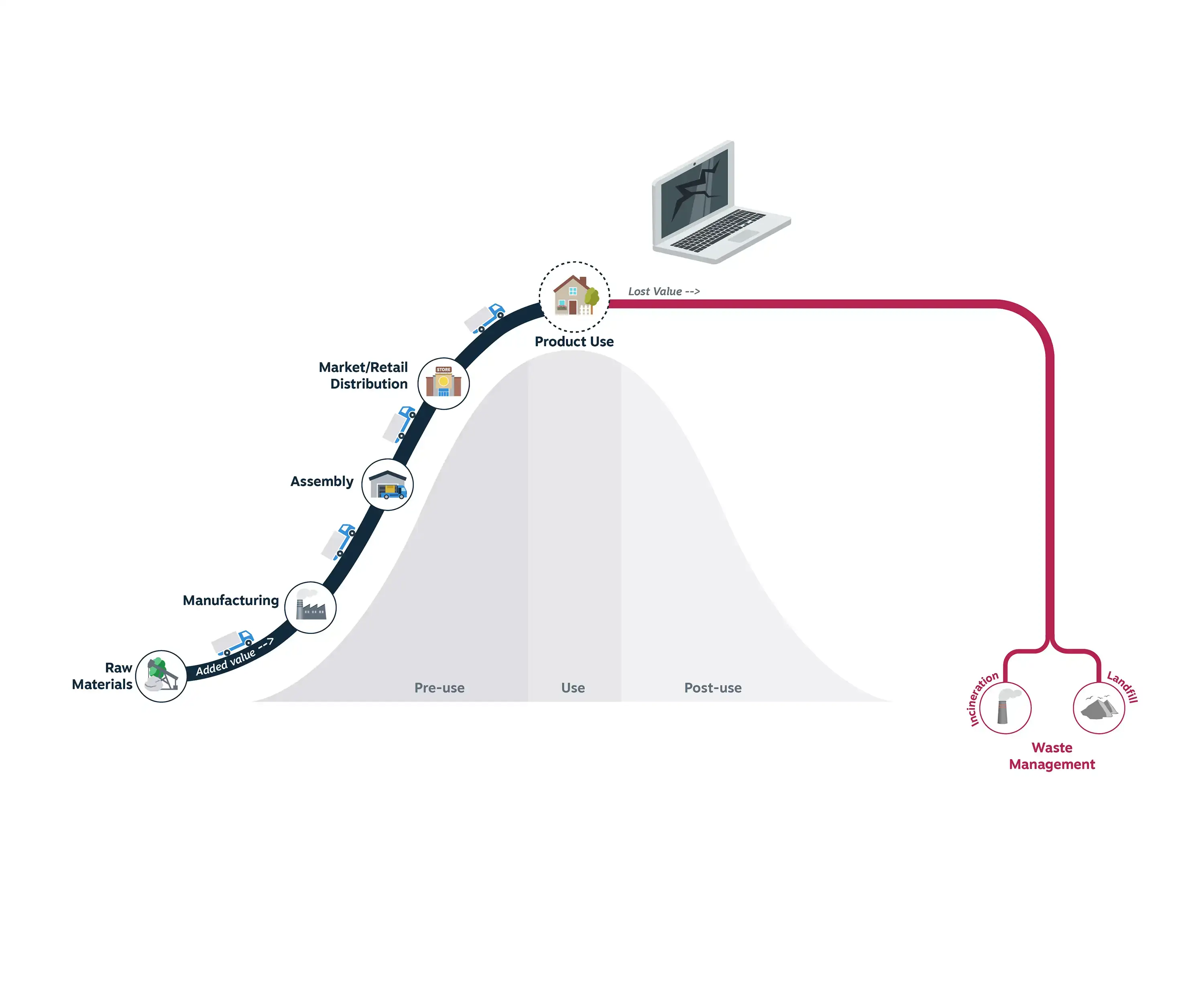

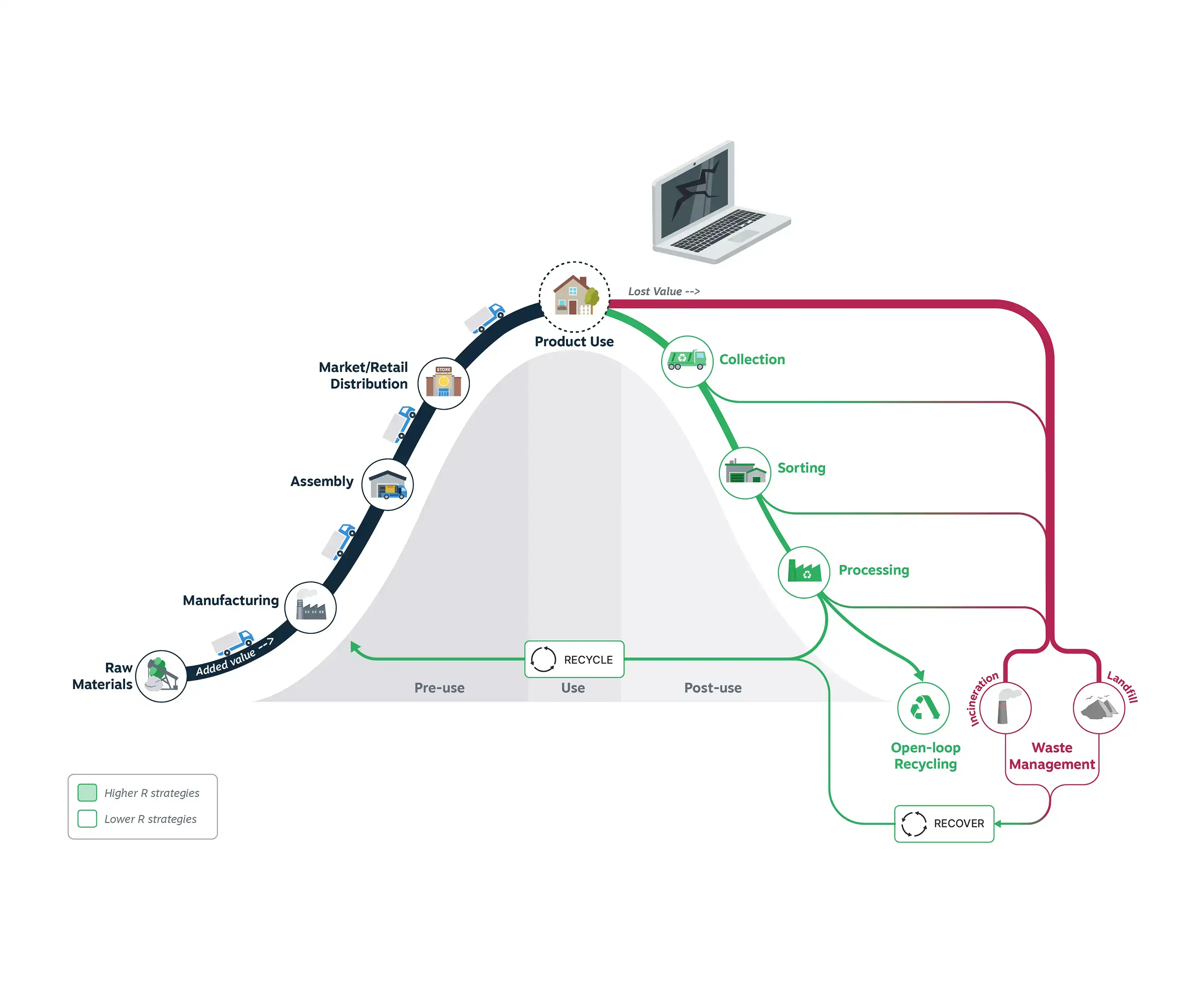

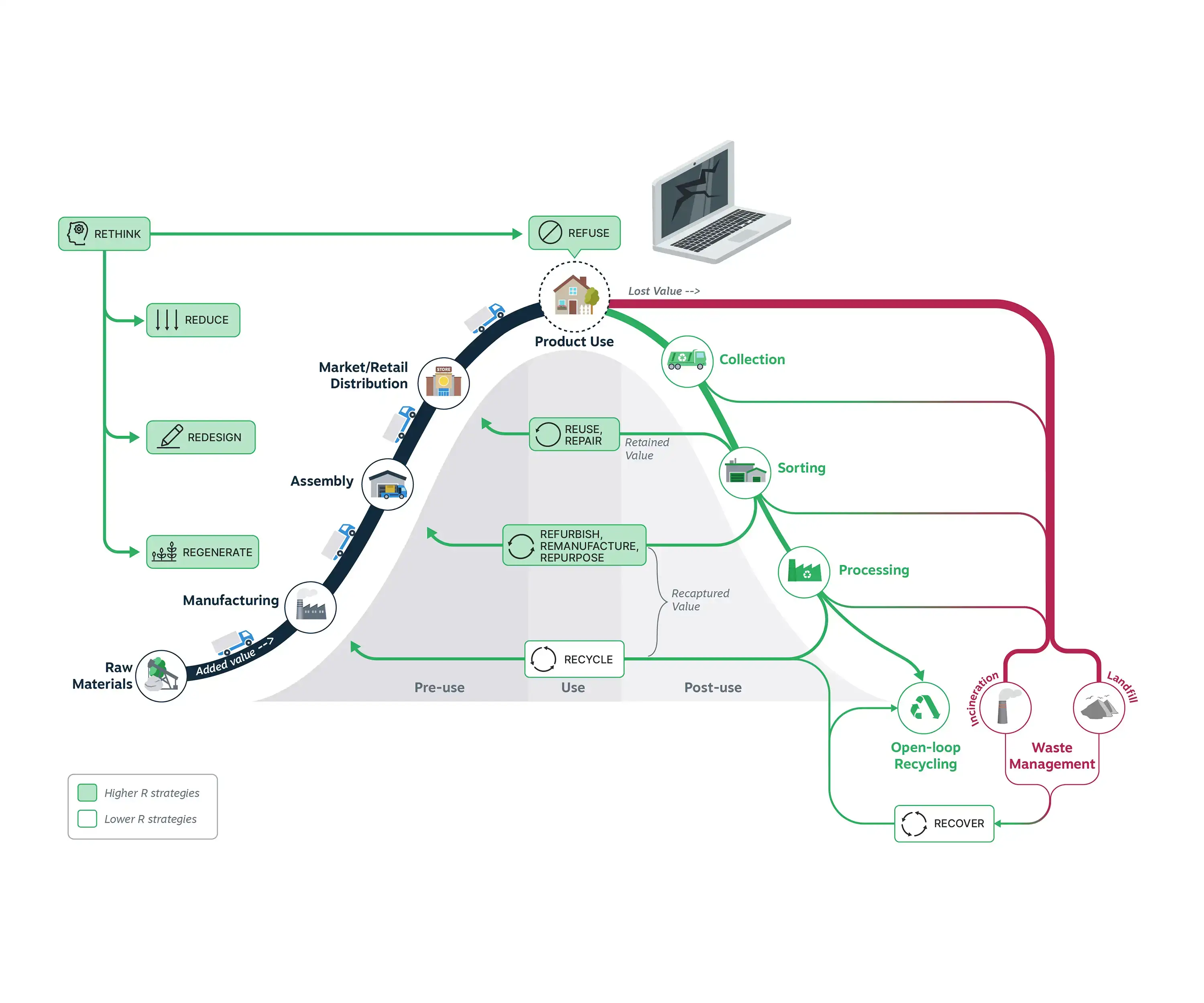

These stages all form the “uphill” journey of a product.

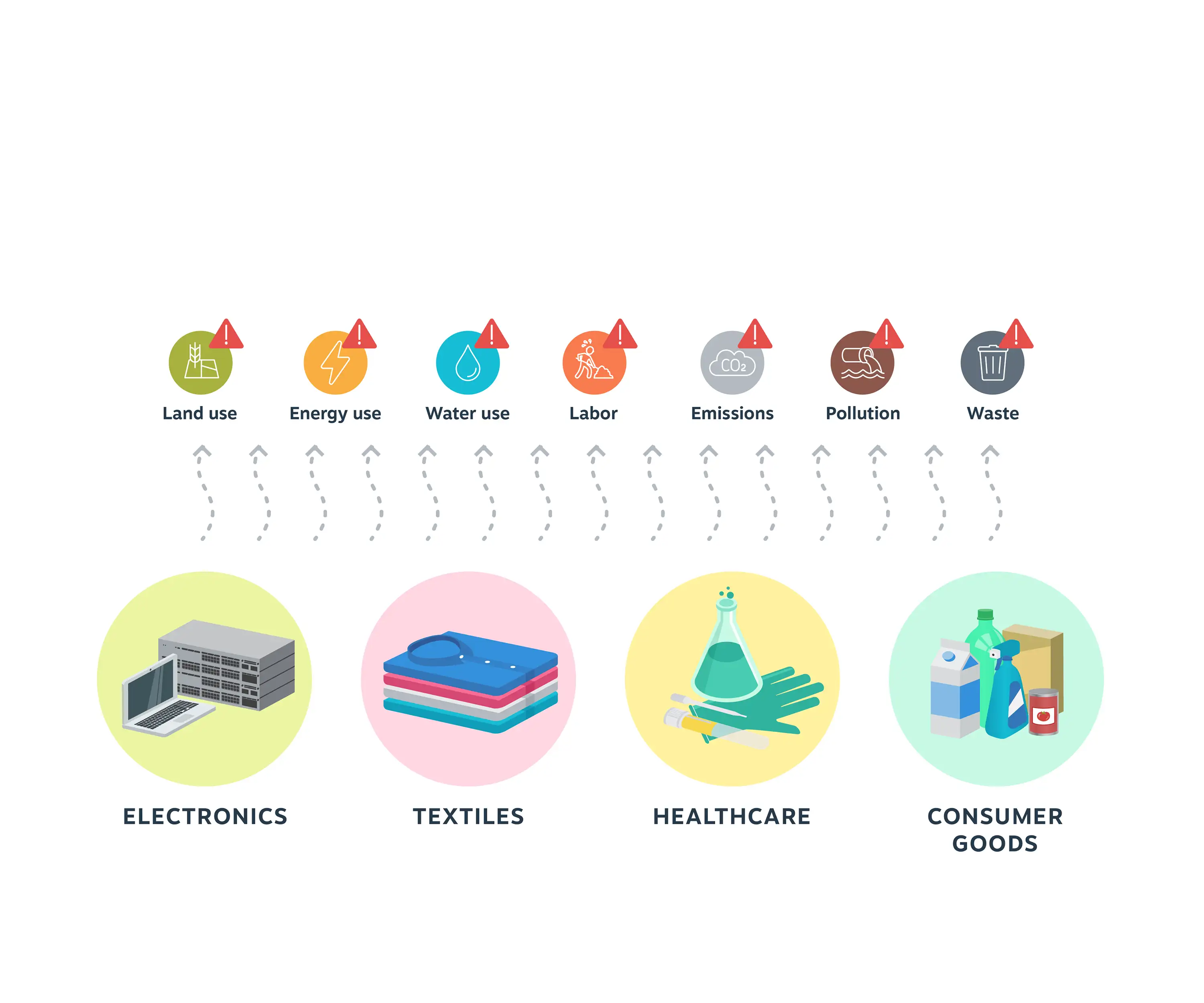

The outputs, on the other hand, include waste, emissions, and other environmental impacts.

For many companies, more than 80% of emissions occur in Scope 3 impacts, particularly purchased goods and materials. This emphasizes the critical need for detailed insights into which products and material hotspots to prioritize to reduce environmental impact.

For a laptop, hotspots include how lithium mining and processing for batteries is draining water reserves in Argentina and Chile. Cobalt mining is linked to genocide in the DRC.

Assessing the impacts of purchased products and materials identifies such hotspots. Companies can then strategize how to mitigate these impacts. This is best done through a comprehensive material flow analysis (MFA) and impact analysis.

Learn more: Metabolic’s Carbon Footprint Assessment

The Greenhouse Gas Protocol, the SBTi (Science-Based Targets initiative), and FLAG (forest, land, and agriculture related emissions) and reporting standards like the CSRD (Corporate Sustainability Reporting Directive) and the ISSB (International Sustainability Standards Board).

Where to start? Data collection and analysis for an impact assessment are the first step to help companies pinpoint what should drive their climate strategy to reduce their overall footprint. Once data for carbon accounting is in place, companies can layer on other supply chain impacts for a more holistic overview of environmental and social risks.

See how this is done in practice: HEMA’s journey to climate neutrality by 2050

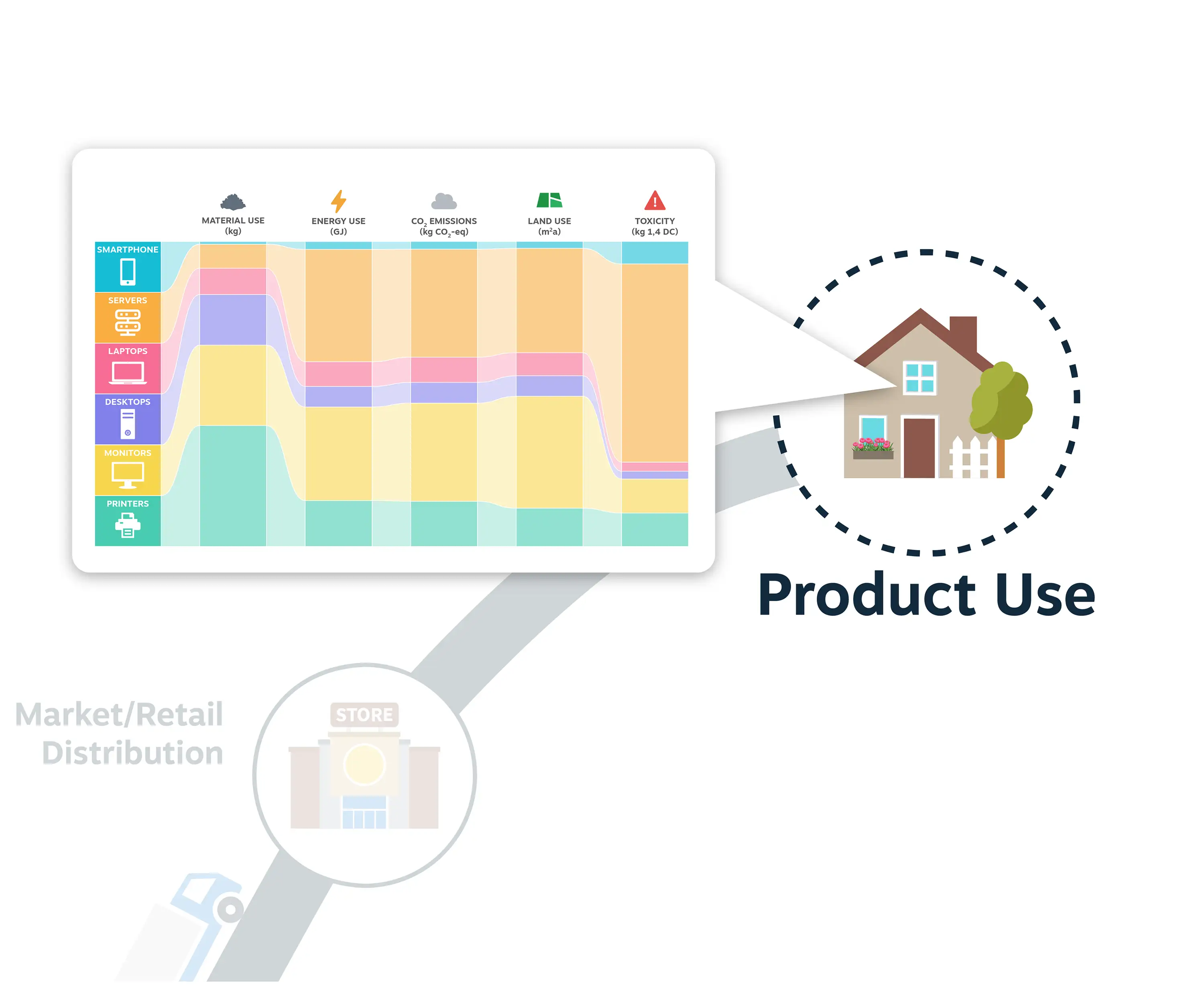

Informed purchasing decisions can minimize that impact. One way to do that is working to identify hotspots in the production system of IT equipment, considering its impact for material use, energy use, emissions, land use, and toxicity (see more in the graphic).

In 2022, we provided Rijkswaterstaat a clear handbook with rules and criteria to define their sustainable and circular procurement strategy to minimize these impacts. Click here to read more.

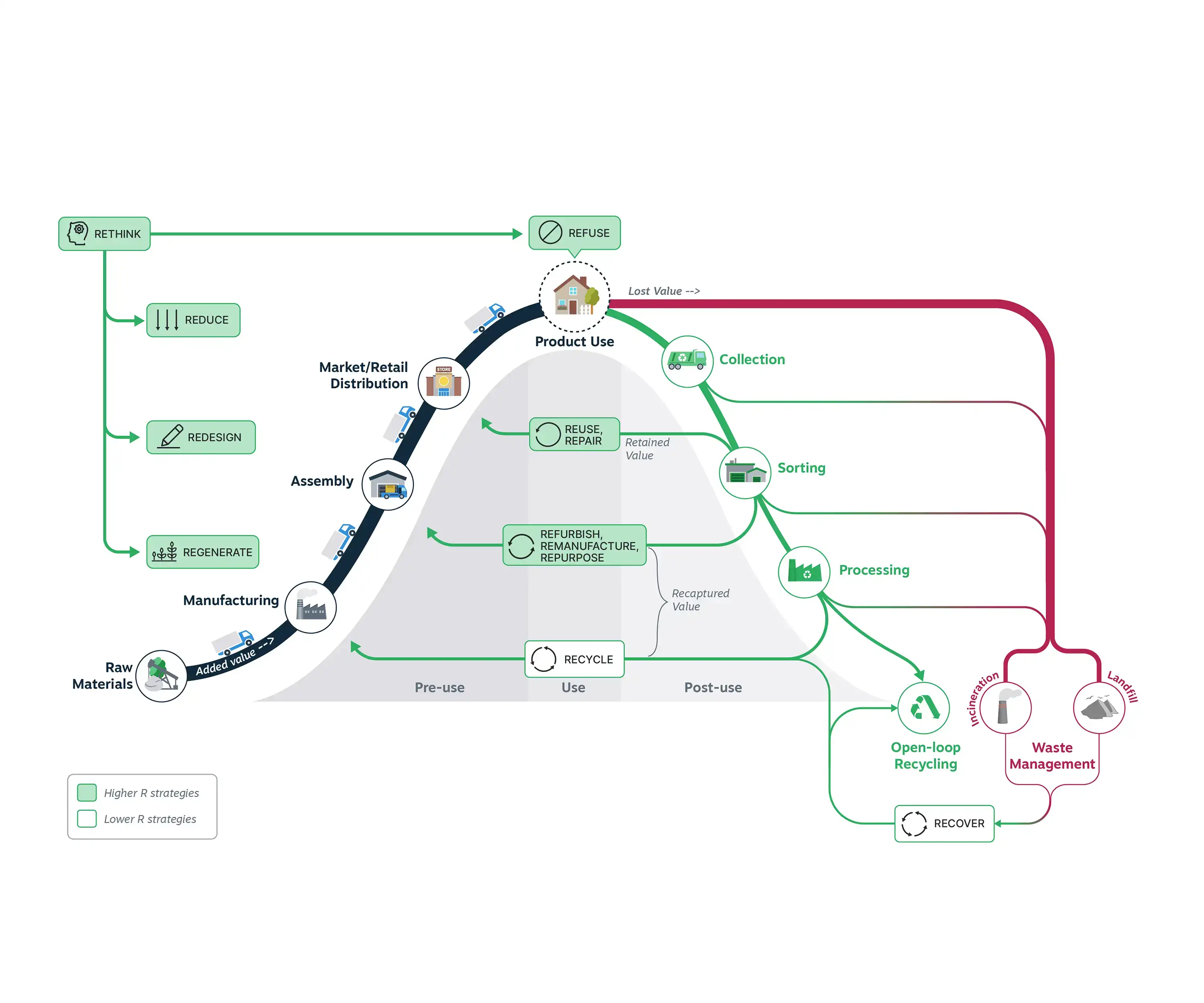

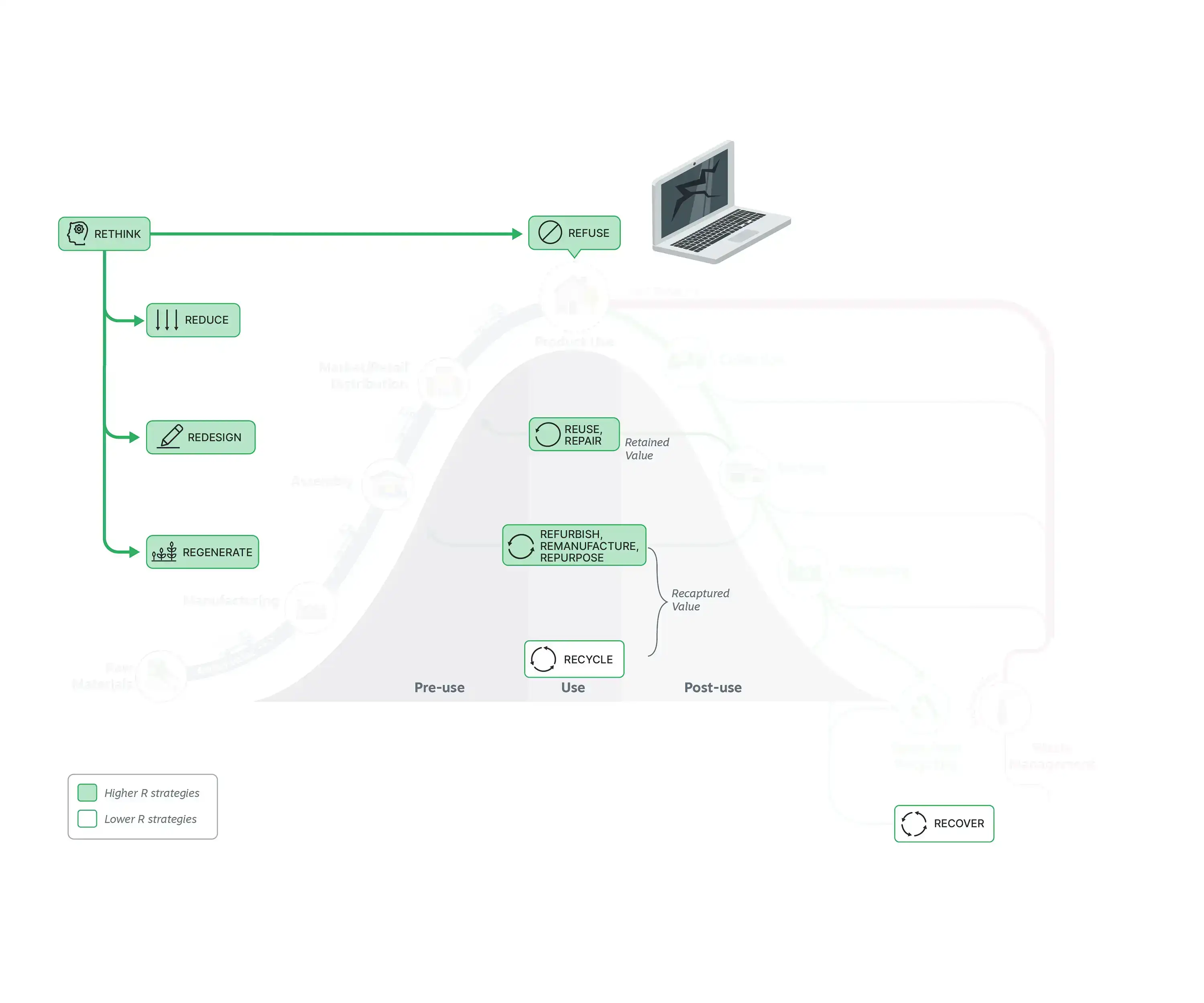

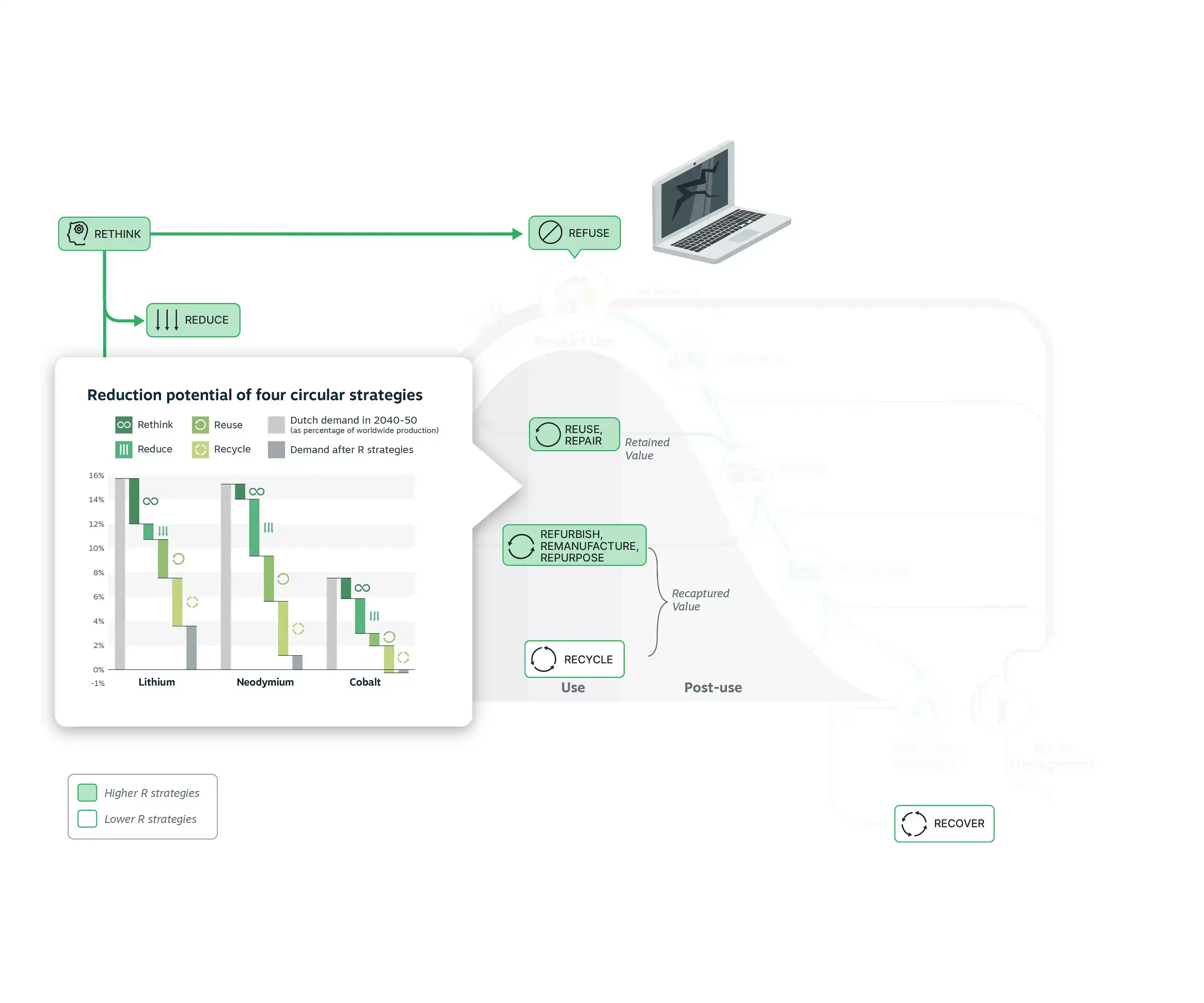

Reuse, Repair, Refurbish, Remanufacture, Repurpose, Recycle and Recover.

Thankfully, these are part of the famous “R strategies,” along with Refuse, Rethink, and Reduce. In addition, Redesign and Regenerate are also crucial interventions to create a truly circular system with reduced impacts.

Placed at different phases of the value chain, these strategies collectively reduce the impact of production and retain the embodied value of products at their highest and best use for as long as possible. It is the circular economy in action.

These products and materials are circulated again without all the harmful impacts associated with upstream production. That's true circularity in action!

Nowadays, producers are also increasingly becoming responsible for what happens to their products at the end of their lifespan (known as Extended Producer Responsibility, or EPR). Especially when it comes to products containing scarce materials, electronics in particular, it is important to retain the product at its highest value for as long as possible.

How can you measure the impact saved by doing so?

Metabolic has created a Circular Interventions Impact Calculator based on the Circular Footprint Formula to evaluate the potential impact savings from applying circular strategies across various product categories, including consumer product returns, take-back scenarios, reverse logistics, and waste diversion.

Discover how this tool can be tailored to your specific needs:

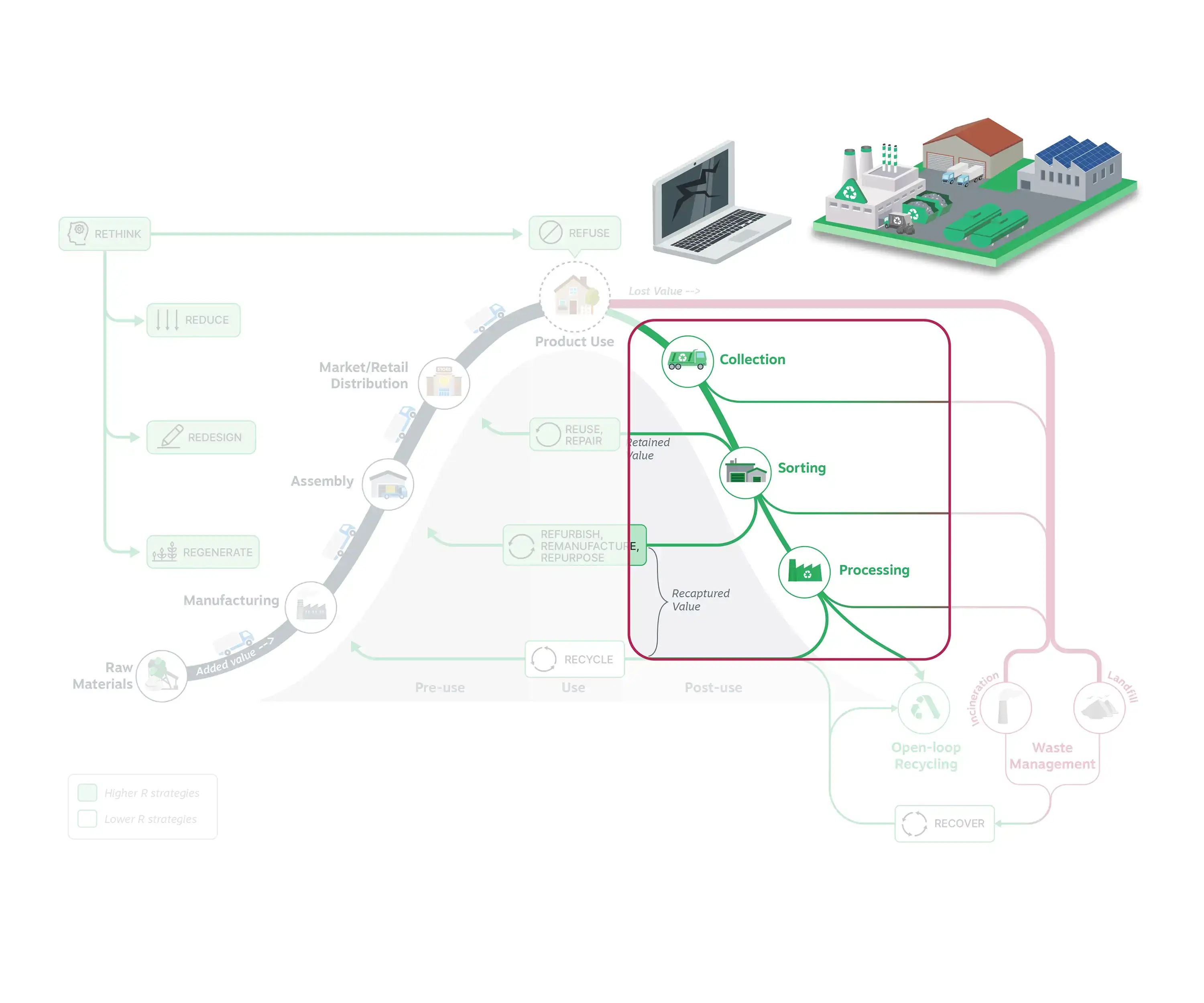

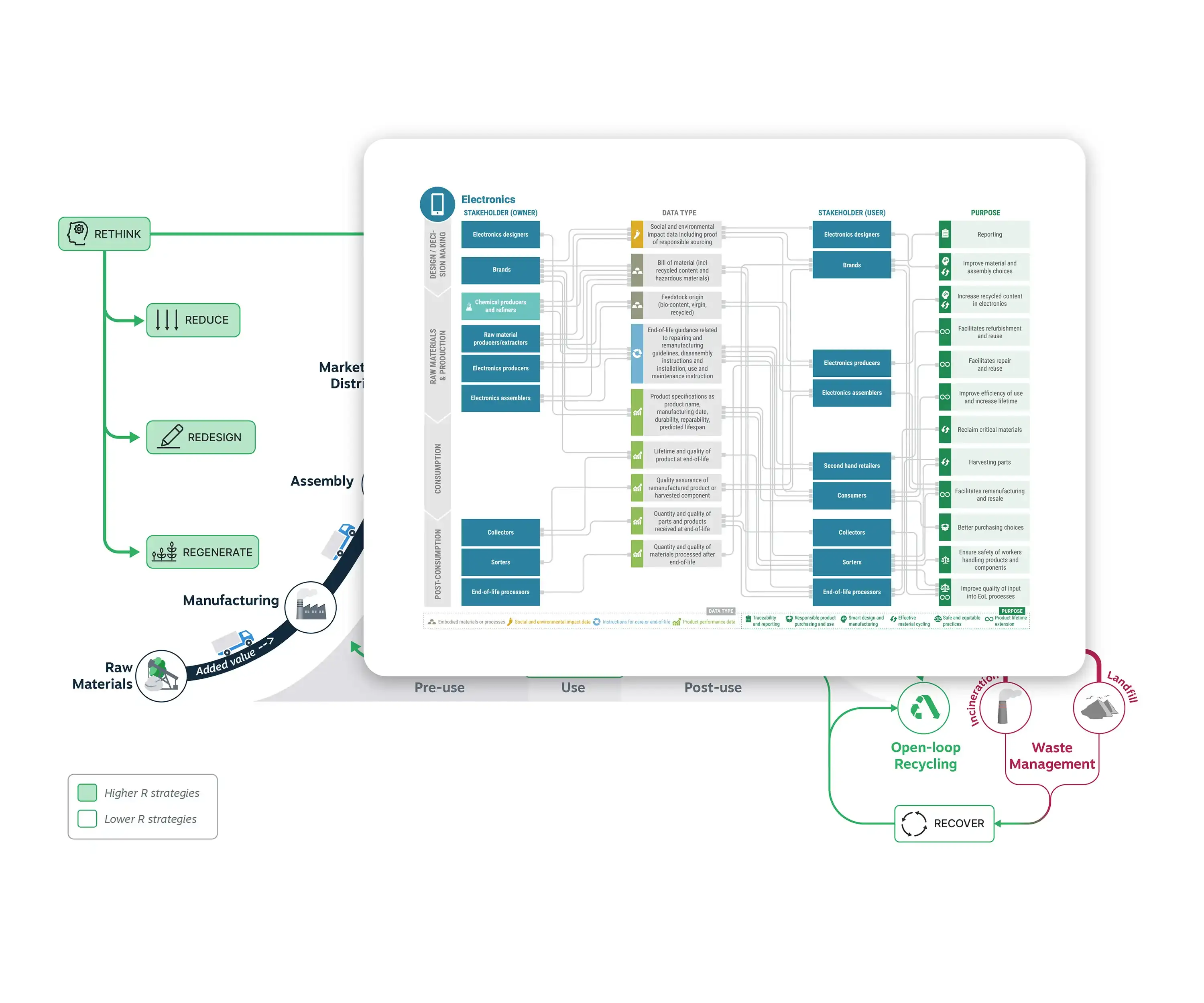

When looking at the end-of-life pathways and trajectories, it’s key to involve producers in conversations with “downstream” partners who collect, sort, and process products and materials for reintegration within the system.

Activities such as stakeholder mapping and visioning workshops overcome common barriers such as siloed thinking. Instead, cross-industry collaboration is absolutely critical for a circular electronics future.

What does this entail? Survey stakeholders, such as electronics producers, users, and recyclers, to assess what would be needed to create a circular and sustainable value chain for electronics.

Check out our work with Responsible Business Alliance!

As described by one electronics producer, “Once we see our downstream as our upstream, we will become a circular value chain.”

Data is crucial for scaling the circular economy to replace the current linear, extractive system focused mainly on the uphill part of a product’s story.

In order to implement circular strategies, mechanisms like Digital Product Passports can facilitate this. In collaboration with the World Business Council for Sustainable Development (WBCSD), we’ve mapped out the information that needs to be communicated between different stakeholders for product and material recirculation across different sectors. Read more here.

Implementing circular solutions is therefore a risk mitigation strategy. In fact, we will only be able to meet society’s surging demand for critical materials when implementing R strategies at scale, with a particular focus on higher R strategies such as Reduce, Reuse, and Repair.

Check out our research on this topic here.

Scroll below and connect with us to shape this future together!