Why do we extract, produce, and transport scarce primary materials from mines around the world, when there are abundant secondary sources throughout our cities?

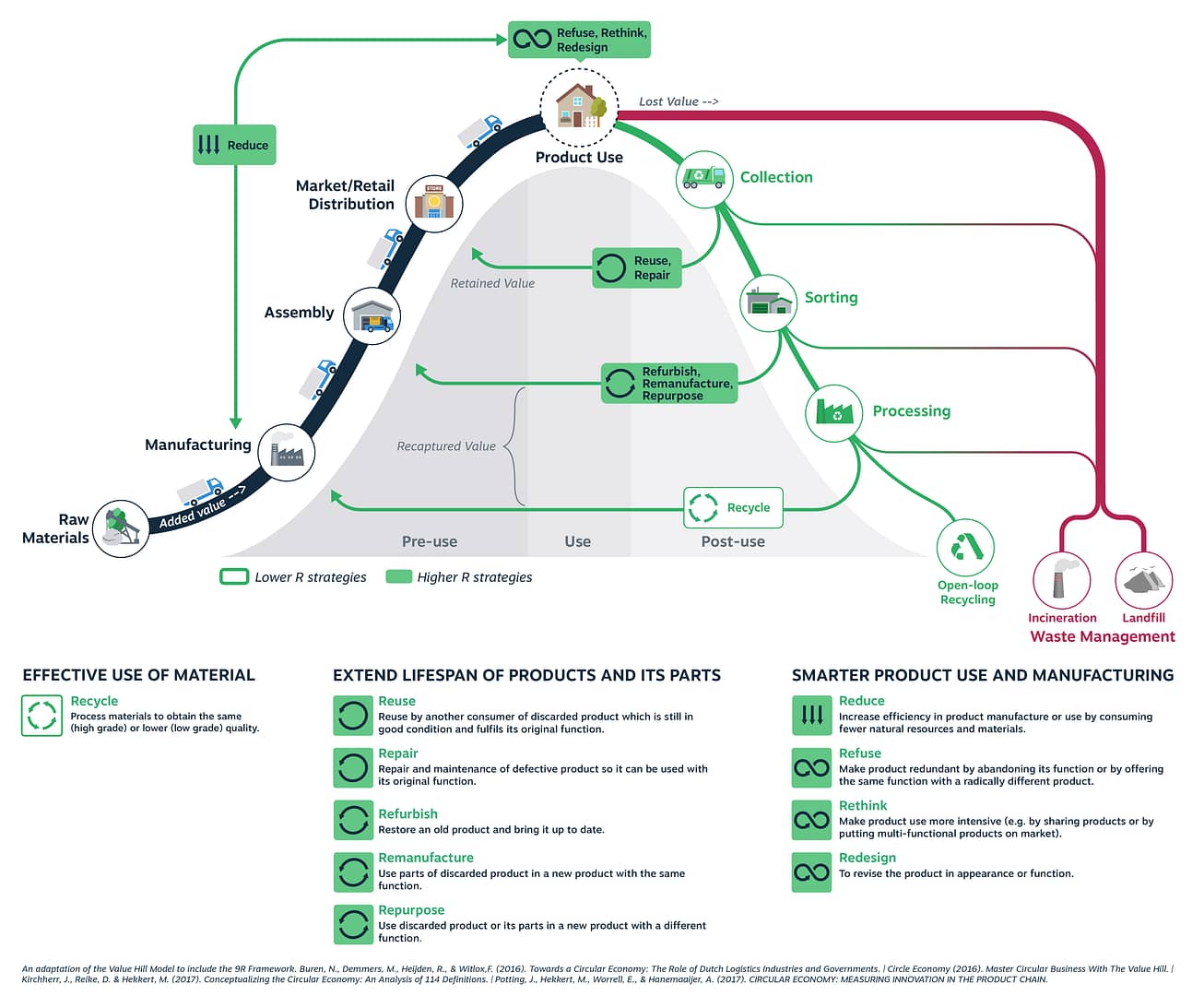

Just like any product, every building has a lifespan. The valuable materials they contain — wood, glass, concrete, metal, electronic or industrial components — often end up in a landfill, incinerated, or downcycled into products of much lower economic value.

The concept of urban mining combats losing such valuable resources. It aims to reduce the amount of virgin materials we mine in the traditional sense. Let’s explore how these efforts are gaining momentum in Dutch cities and uncover partnerships and services that develop circular products recovering a significant amount of materials. Let’s see how urban jungles ring with virtual gold mines.

What is urban mining?

Urban mining is the process of recovering and reusing a city’s waste materials. These materials are recovered from buildings, infrastructure, or products that have become obsolete. Once an object reaches the end of its useful life—whether it’s a vehicle, electronic device, or building no longer meeting safety standards—its materials become ripe for reuse. While urban mining, especially for metals from cars and electronics, isn’t a novel concept, embracing it more broadly and actively across urban landscapes is one crucial way to preserve our limited resources and remain within our planetary boundaries.

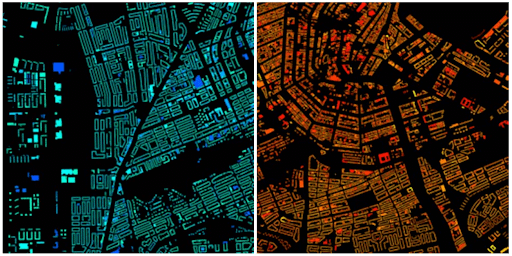

It is just as important to ensure industries can trust in a reliable supply of high-quality secondary materials. Without this trust, industries will not adopt these materials, impeding the transition to a circular built environment. The first step in any mining process is physically searching for resources, minerals, and precious metals. For example, special imaging seen here shows Amsterdam’s buildings contain a wealth of steel, copper, aluminum, and lead.

The Raw Materials of Urban Mining: What Can Be Reclaimed?

The most common materials in the urban environment are from construction and demolition. In the EU, demolition, including renovation, generates roughly 124 metric tonnes (Mt) of waste a year, which comes close to the weight of 12,277 Eiffel Towers (SOURCE). So, what happens when a building is demolished? We estimated that 71% of demolished materials in Europe are recycled or backfilled, most of it being downcycled.

For example, concrete might find its way into road fillings but rarely into new buildings, even though its properties make it a good candidate for reuse.

Reusing these tonnes of waste materials for new construction projects has many advantages. The materials are already available in the city, so there would be no need for disruptive changes in the supply chain. This would increase resilience in the event of supply chain disruption caused by transport delays, material scarcity, or increasing material prices. For all cities with circular targets, urban mining helps to maintain the materials at their highest value for as long as possible.

Rotterdam’s Journey from Waste to Resource Through Urban Mining

Let’s look at the work we conducted in Rotterdam to illustrate how urban mining helps the city become circular and generate value from what was long treated as simple waste. The large harbor city has set ambitious circularity targets for 2030, including reducing the use of primary raw materials by 50%. The city also wants to create 3,500 to 7,000 jobs that contribute directly to the circular economy.

Meanwhile, Rotterdam discards 400,000 Mt of waste every year — a huge opportunity for recovery and reuse. We’ve identified buildings in the city that are scheduled for demolition up to the year 2030 and found that they contain 817,000 Mt of materials available for harvest within that time frame. Data indicates a downcycling rate of 85%, which means there is a lot of potential not only to recycle but also to reuse, a practice that maintains the value of an existing material or building component.

Our report on how to bring residential construction in the Netherlands within planetary boundaries (Woningbouw binnen planetaire grenzen) shows that using secondary materials can reduce primary material use by 18% and CO2 emissions by 40%, especially in terraced houses. This demonstrates the value of urban mining and circular materials in reducing environmental impacts at the building level.

A Treasure Trove of Secondary Materials sits in the Construction Waste

While construction waste provides by far the highest tonnage in the urban mine, everything in the city can be reused at the end of its useful life. Urban mining can be applied to electronic waste, which contains a literal treasure trove of gold and other precious metals, as well as to entire products and appliances. Anything in a city is part of the urban mine. Amsterdam claimed 69,000 unwanted bicycles in 2018 alone, and fishes more than 15,000 bikes out of the canals every year. Each and every one represents valuable metals, spare parts, ready-made frames, and other components that can be reused locally or to jump-start new production processes.

However, just as big cities are called the “concrete jungle”, the buildings we see all around us are the biggest and most valuable part of any urban mine. Not just concrete, or the steel that reinforces our modern buildings, but the wood, the glass, the copper pipes, the aluminum facades, the roof tiles, bricks, or even the iron railings on our balconies. All of these are valuable finished products that have already gone through a long supply chain.

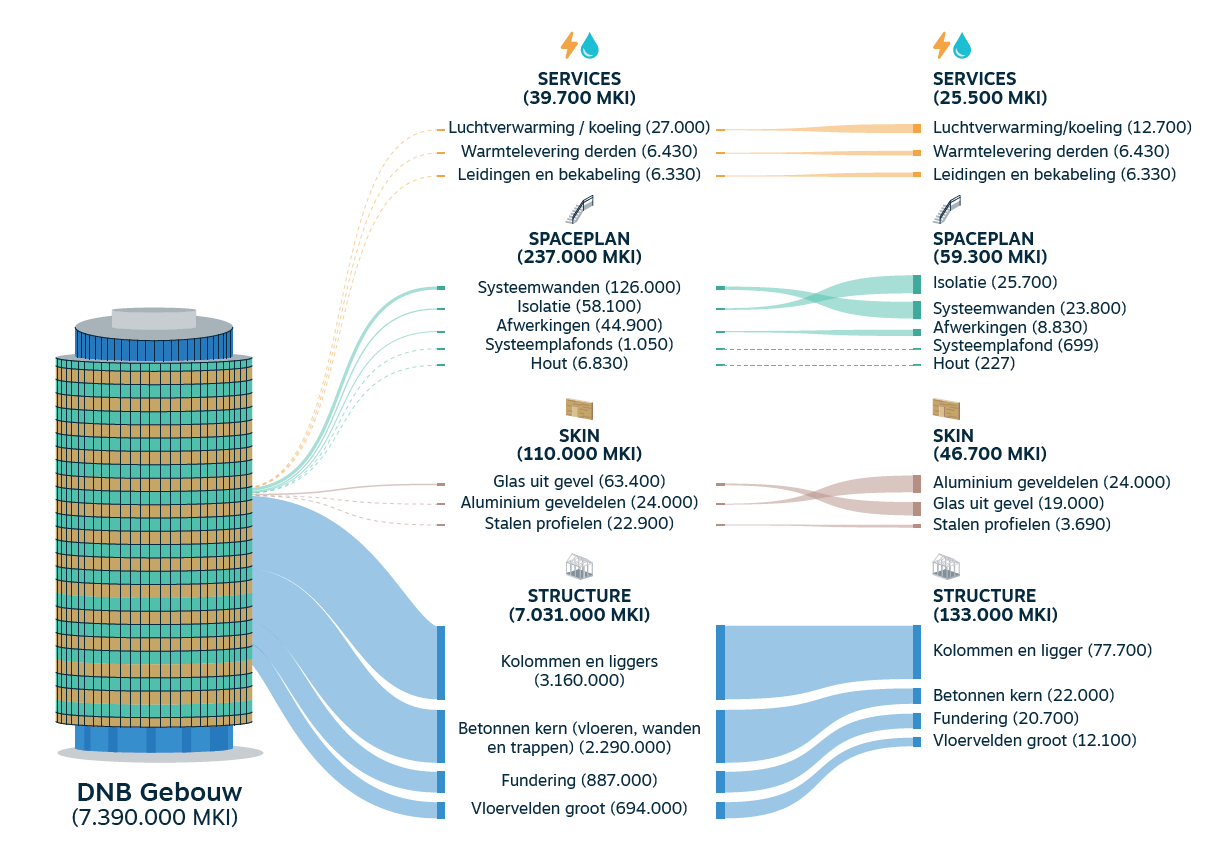

Urban mining potential for the building of De Nederlandsche Bank (Dutch National Bank)

The Concrete Path to Lower CO2 Emissions

Consider the process and life cycle of a major construction product such as concrete. It starts with sourcing the materials required for its creation. Stone and sand are extracted to be used in the mixture, combined with cement, derived from limestone, silica, clay, and other materials. To reinforce concrete, steel is integrated, its production consuming 20 gigajoules of energy per ton and resulting in 1.83 million tons of CO2 emissions, alongside significant air and water pollution from iron ore mining. This amalgamation of components leads to more complex products.

Subsequent steps, including manufacturing, transportation, and labor, demand substantial time, energy, and resources, which contribute to greenhouse gas emissions and environmental impact.

Now we see that each stage, from extraction to assembly, adds value to the end product. In a low-carbon and circular construction sector, the goal is to maximize this value retention, especially in structures earmarked for demolition. By carefully disassembling buildings and repurposing materials, high-value retention is achievable.

Our partner, New Horizon, champions circular construction with its Urban Mining Concrete. This innovative solution repurposes materials from demolished sites to produce new concrete. By reclaiming sand, gravel, and active cement through their Smart Liberator technology, this concrete substantially lowers CO2 emissions, aligning with sustainability goals. Specifically, Urban Mining Concrete achieves a 60-80% reduction in CO2 emissions compared to traditional concrete.

This approach can be found for almost all materials. Another partner of ours, Luijtgaarden for example specializes in providing sustainable roofing solutions by reusing ceramic roof tiles. Each tile is carefully sorted and inspected to meet quality standards, and comes with a warranty of up to 10 years. Luijtgaarden maintain a large inventory of used tiles, ensuring a variety of options for renovation projects. This reduces construction waste and paves the circular path for the sector.

Urban Mining’s Structural Hurdles

Despite this kind of innovations, broader adoption is slow, with only 8% of materials being reused in the Netherlands. Our analysis with local stakeholders in Stadregio Parkstad identified both practical and systemic obstacles to scaling the use of circular products. For instance, while refurbished ceiling panels significantly lower CO2 emissions, they face affordability challenges. The costs associated with disassembly and refurbishment, along with a reliance on subsidized labor, hinder their widespread adoption. The interplay between environmental benefits and financial viability remains one of the key complexities in the adoption of circular solutions.

At a systemic level, circular solution providers face multiple challenges. There is a lack of understanding among building owners—including public authorities and housing associations—as well as contractors, regarding potential circular solution chains and their regional or national impacts. It’s essential to unlock material supply and adapt processes for reusing materials from buildings, which includes revising demolition policies and fostering collaboration. Implementing circular procurement policies also demands careful consideration in the tendering processes for both public and private sectors, ensuring interdisciplinary cooperation and securing these efforts with suitable contract forms.

Paving the Way with Circular cities and regions

Meanwhile, the impact of secondary material reuse remains latent. Despite the profound impact circular building products and materials pose, adopting urban mining is limited and supply constraints diminish the strategy’s overall effectiveness in CO2 reduction on a larger scale.

There are systemic barriers that can only be overcome when public organizations play a pivotal role in adopting urban mining initiatives. This begins with providing the necessary knowledge and infrastructure to foster circular initiatives and ensuring that policies support the transition to a low-carbon, circular construction sector.

Ambitious cities and regions lead the transformation by taking these key steps:

- adapting policies for demolition and material recovery

- emphasizing a collaborative approach across various stakeholders

- ensuring supply meets demand through innovative urban mining practices

- enhancing the visibility of promising circular chains

- addressing logistical challenges

- matching physical and digital aspects for material reuse

This strategic focus not only aligns with ambitious policy goals for circularity in cities but also showcases the vast opportunities within the urban mine, ultimately facilitating the transition towards circular and regional supply chains.

Cities are the engines of our global economy. Home to most of the world’s population, they are centers of human creativity, diversity, and interaction, but their resource use and emissions extend beyond their footprint. At Metabolic we aim to reinvent our cities as healthy, sustainable, and inclusive places that foster strong communities and allow all species to flourish, while remaining within the limits of the planet. We can make this a reality by working with cities and regions to redesign our urban future.