Table of Contents

Executive summary

Charlotte is the first city in the United States to make a commitment to adopting the circular economy as a public sector strategy. In its circular future, all of the material resources that now end up in landfills will be the basis for Charlotte’s next industrial revolution: the foundation for an era of green manufacturing that unlocks new technological advances, increases local resilience, and supports workforce development.

Our report, “Circular Charlotte: towards a zero waste and inclusive city,” explores how Charlotte can start implementing a strategy to become the first circular city in the United States. We investigate how many valuable resources are currently lost through Charlotte’s waste system, and how these could be diverted into new, high-value uses. We present a vision, co-created with stakeholders from the city, for how a Circular Charlotte could look and function. Finally, we describe a roadmap of actions that should be taken on the pathway towards this vision, and detail five initial business cases that can serve as a starting point for action.

Growth brings transition opportunities

Charlotte is in the midst of a building boom. This expansion of the city points to Charlotte’s increasing popularity as a place to live and work: it is now ranked as one of the fastest-growing metropolitan regions in the United States (Thomas, 2018) and was recently named the number one city for attracting millennials (Abadi, 2017). Beyond changing physically, Charlotte is undergoing a broader transformation in its character, evolving from a banking-focused city with a history of manufacturing and logistics, to a dynamic urban center with unique specialties in high-tech industry. This growth is not only an opportunity to cash in on Charlotte’s successes, but also to address challenges, such as economic mobility, on which Charlotte is currently ranked lowest out of America’s 50 largest metro areas (Chetty, 2017).

The circular economy – a new economic system that is regenerative and waste-free by design – can not only eliminate negative environmental impacts and create new sources of value, but also be used to bridge the wealth divide and create new pathways for upward mobility in Charlotte. Within a circular economy, products and materials are circulated at high value for as long as possible, extending the life of products and enabling high-value component and material recovery for reuse or recycling. The systemic transformation required for a circular economy – from the development of new technologies, to the evolution of new forms of collaboration and business models – has also been shown to have great potential in generating new employment and creating opportunities for skills development.

The Circular Economy

The vast majority of our economic system can currently be defined as linear. We extract resources, which are then transformed to products via the use of labor, energy, and money, and then, soon after their use, these products are thrown away. Every time a product that we have crafted and manufactured with care ends up in landfill, not only do we lose the physical resources it is made up of, but also all of the time and energy that went into its creation. McKinsey estimated that up to 630 billion dollars a year is lost in Europe alone through the loss of materials in the linear economy (EMF & McKinsey, 2011).

In parallel, these material losses translate to unrealized employment potential. The U.S. EPA and the Institute for Local Self Reliance estimate that low-value activities that result in material losses (like incineration and landfilling), only generate 1–6 jobs per 10,000 tons of goods disposed of. Recycling generates an estimated 36 jobs for the same amount of material, while reuse and refurbishment are by far the biggest winners, creating almost 300 jobs for each 10,000 tons of “waste.”

To move towards a circular economy, where the value-generating life-cycles of products are extended to the maximum extent possible, we should:

- Design all products for easy repair, disassembly, and full recyclability.

- Create the necessary business structures and incentives to get these materials back into the economy at their highest possible value (preferably as whole products or components).

- Strive to use only responsibly-sourced renewable resources for both energy and material provision.

- Avoid the use of toxic substances that may continue to circulate in our environment.

Successfully achieving this transition is not simply about product reuse and recycling: it means a systems change that requires a new mindset. Preserving the complexity and value of our products should be structurally incentivized, and negative impacts on people and the environment should be eliminated by design. This transition can be supported through alternative business models and purchasing patterns that will support the recovery of materials, such as leasing models and advanced approaches to extended producer responsibility (systems that make manufacturers responsible for what they create and sell, even after the products are sold). Perhaps most importantly, achieving this transition will require a shared vision and strong leadership from both government and civil society.

Vision of a Circular Charlotte

If we take these high level ideas about the circular economy and actually apply them to Charlotte, what kind of changes would potentially take place? Here we envision, from a 2050 perspective, how Charlotte might look if it achieves the full spectrum of a circular economy. We have organized the vision around four thematic areas. For each of these four areas of performance, we have also developed Key Performance Indicators (KPIs) to monitor Charlotte’s progress (see page 30). Though some of these ideas may seem farther off in the future than others, every plan starts with imagining the reality we aim to achieve. The picture we describe here will certainly not be a perfect reflection of what actually transpires, but it can provide a starting narrative and inspiration for the next decades of Charlotte’s development.

1. Charlotte as a Zero Waste City

In 2050, Charlotte might proudly call itself a Zero Waste City, where 98% of all residual materials are separately collected. Every household could be equipped with smart sorting containers with built-in technologies to tell users if they’ve sorted something incorrectly. Residents would get reward points paid directly into their digital wallets for every pound of correctly sorted waste. They could use their earnings for the purchase of local goods branded with the Circular Charlotte label, many of which might have been remanufactured or grown from those same residual streams. If they have reward points left over, they could also use them to pay for their fully-renewable energy bill, or even pay their taxes. A real-time resource monitoring platform, the Charlotte Circularity Dashboard, would continuously reports how much is available of different kinds of residual goods – from citrus peels to old shoes. These resources would be automatically diverted to various processing facilities throughout the city, run by large companies and small entrepreneurs alike. The Dashboard would keep a record of orders placed requesting different materials, and ships off materials to the earliest bidders. Due to Charlotte’s strong position as a logistics hub, the city would also accept and process materials from nearby counties, adding to the base of resources used for local manufacturing.

2. Charlotte as a resilient and healthy city

As other circular industries develop, Charlotte and its surrounding region could become increasingly independent of foreign imports, with almost all materials sourced from local cycles. Even local food production has the potential to grow immensely, with the advancement of vertical farming technology and the reuse of organic waste streams as fertilizer. Most of Charlotte’s schools would also have their own small-scale aquaponics facilities, which would be used both for hands-on science education as well as to provide farm-fresh produce and fish to the schools’ cafeterias. Further efforts to increase the city’s health and resilience could focus on the decentralization of certain utility services. Renewable energy, decentralized battery storage, and smart distribution of energy through the city’s smart grid could make Charlotte’s energy system resistant to the impact of storms or floods, with most damage remaining localized.

3. Charlotte as an innovative city of the future

With Charlotte’s innovations in waste collection and sorting, which would result in the supply of previously-unavailable high-quality and pure resource streams, a whole new cluster of industries could began to develop throughout the city. New product development would explode in the early 2020s. At first, the major focus of R&D activities would be on processing textiles, plastics, and construction wastes. In 2023, CharM, the city’s newly-opened materials lab, a joint project of several of Charlotte’s incubators and accelerators, would begin experimenting on how to convert collected organic wastes into new materials – like clothing, furnishings, and biodegradable packaging. The strong need for materials and product innovation because of the city’s ambitious circularity goals would also lead University of North Carolina Charlotte to establish a new educational facility, the Charlotte Institute of Circular Design and Engineering (CICDE). The Circular Charlotte brand would help the city consolidate its leading position globally, and cement Charlotte’s top position in global rankings such as the Sustainable Cities Index.

4. Charlotte as a city with opportunities for all

By 2050, Charlotte could have less than 0.5% of its population living in poverty. Initial efforts on establishing circular industry and innovation would be largely focused on skill development, training, and inclusive programs designed to uplift those who are economically disadvantaged. In 2019, the city’s solid waste department could establish a test rehabilitation program for the homeless community, providing employment in plastic waste sorting and remanufacturing. Plastic wastes, which are of too low a quality for automated processing at that time, would be sorted, washed, and shredded for the production of small batches of local products like street furniture, waste bins, and trophies for school sporting events. Some of the trainees involved in the pilot program could go on to start their own companies focused on recycling and product manufacturing.

How Circular is Charlotte today?

This graphic shows the types of wastes generated in Charlotte and where they ultimately end up. Only 11.5% of the materials that currently enter Charlotte’s waste system each year are recycled or composted. In order to make Charlotte circular, the city will need to make it convenient and affordable for households and businesses to recycle and develop products and markets that can accept recycled materials. For example, 16% of the waste that ends up in landfill is food waste, partly because there are no free organic waste recycling programs that provide an alternative to landfill.

Uncovering the potential of circularity

This figure shows the potential mass (y-axis), revenue potential (x-axis), and job creation potential (bubble size) for each of the material categories currently ending up in Charlotte’s landfills.

From the graphic, we can see that there is a significant amount of value going literally to waste. In total, we calculate a residual market value of $111 million in material value and a job creation potential of more than 2,000 new jobs that would be created if these materials were recycled.

It is important to note that here we’ve only considered the residual scrap value of the materials when they are sold for recycling. When circular business strategies are applied (such as refurbishment, repair, or remanufacturing), more value can be retained than what materials are worth on the scrap market. Design for modularity and disassembly can further increase the value that can be recovered from waste materials, though this also requires participation from parties upstream in the value chain.

This analysis shows the value of all the materials once they have been collected, excluding processing and collection costs. The business cases we developed in Chapter 5 of this report show both the costs and revenues of selected material streams when they are processed in a circular manner.

Circular opportunities

If done right, a circular economy in Charlotte will create opportunities for local employment, reduce the socio-economic divide in the city, and establish new industries that lead to greater local resilience and economic vitality. Ideally no waste will be going to landfill and all materials flowing through the city will be used as the basis for new circular manufacturing. By definition, training in new skills (such as product repair, remanufacturing, or circular demolition techniques) is required for the transition, creating job potential. In addition to the socioeconomic opportunities that this pathway unlocks, there are a number of other benefits.

Landfilling materials is associated with both financial costs and environmental impacts. Charlotte has recently adopted a low carbon strategy, through which it will strive for a net annual CO2e emission of less than two tons per person. Reducing the total waste-to-landfill is one way of reducing emissions. Conventional landfilling of municipal solid wastes contributes between 138-601 lbs CO2e per ton (Manfredi et al., 2009). In total, between 0.08 – 0.34 tons of direct CO2e emissions per person can be reduced by shifting to a completely zero-waste system.

An additional issue is that sending waste to landfill increases the demand for virgin resources, and can exacerbate impacts upstream associated with material extraction. Recycling materials such as plastic and paper can prevent the need for new production of these materials, while even waste incineration can reduce the need for fossil fuels such as natural gas or coal in electricity production. As an example, you can consider wood and paper production, which has a large land footprint. To produce the wood and paper that is currently landfilled in Charlotte, you would need an area of nearly 17 square miles. To put this in perspective, you can consider that this is around 5.6% the area of Charlotte or more than 100 times the area of Charlotte’s Freedom Park. A large share of this land area could be left unexploited if paper and wood were recycled instead of sent to landfill.

Finally, activities of other stakeholders outside of the scope of Charlotte can have a large impact on how the waste system of Charlotte functions and the opportunities that can be achieved with circularity. One example is China’s decision to limit the import of recyclables to those of a high quality, due to environmental and health reasons.

Chinese policy on materials accepted and the quality of recyclates will have a large impact on global markets for recyclables and is expected to have a large negative impact on United States recycling businesses and threaten thousands of jobs (Rosengren, 2017). In some cities in the United States, this ban has already resulted in the refusal of certain types of plastics for recycling (van Fleet, 2017).

By adopting a circular economy strategy, Charlotte can insulate itself from these kinds of impacts and provide local solutions for neighboring counties.

Business Cases for a Circular Charlotte

Through our analysis, we have shown that the combined residual value of the waste streams currently ending up in Charlotte’s landfills amounts to $111 million per year. The top four opportunities of plastic, textiles, construction and demolition waste (C&D), and organics when taken together can reduce landfill mass by nearly 65%, create just under 2,000 jobs, and generate nearly $80 million in revenue.

These amounts do not take into account the cost of collection or processing, nor do they take into account the real added value that can be generated if these materials are not sold as scrap, but instead turned into higher-value products.

To delve deeper into the real costs and potential value generated through resource processing and recovery, we explore five business cases for circular business models that fit the regional context, matched with local interest from stakeholders, or addressed some of the most impactful or problematic waste flows.

These five cases include:

- Developing a local supply chain manager to organize a closed-loop textiles chain for linens and uniforms used in hotels, hospitals, etc.

- Scaling up food waste collection and establishing a commercial-scale facility to recycle food waste into larvae for livestock feed.

- Setting up a Materials Innovation Lab for student entrepreneurs to develop innovations for upcycling specific waste fractions into new products.

- Setting up a incentivized reverse logistics system to provide households with an incentive to recycle materials at a high quality.

- Establishing a circular concrete chain in Charlotte and producing new concrete from recycled concrete and post-consumer glass.

While these business cases cover a relatively small share of the wastes that are going to landfill (around 11-15%), they can result in significant benefits in terms of job creation, CO2e emissions reduction, and most importantly in terms of building local capacity for circular economy innovation. Out of a set of 29 Key Performance Indicators (KPIs) we propose to measure circularity in the city, each business case can improve between 13-19 indicators.

Taken together, we estimate that these business cases can generate between $22 and $34 million in revenue (making more money as they grow over time), and $6.4 million in profit per year once they are established. Since this is based on only 11-15% of the mass of material going to landfill, it can be seen as in line with (or exceeding) the rough estimates of material value from our revenue assessment.

Developing a strategy for Charlotte

Barriers

The magnitude of the transformation that has to happen in Charlotte to achieve the circularity goals outlined in the strategy will require a coordinated set of actions over a number of years, supported by strong leadership from local government, the private sector, and civil society. There are still some significant barriers to tackle along the way (see page 54).

In conversations with stakeholders, we identified a range of barriers – both real and perceived – that need to be addressed through the city’s circular economy strategy.

One key barrier is that there are still some gaps in the physical and technological infrastructure that we need for a transition to a circular economy. For instance, Charlotte currently has no means for recycling styrofoam, plastic dinnerware and cutlery, aluminum or plastic foils and wraps, diapers, ceramics, or any glass that is not used in packaging (glassware, plate glass).

Perhaps more importantly, the majority of products on the market are not designed for high-value reuse and recycling. They are often made of mixed materials, have unknown additives, are assembled with glues making them difficult to take apart, or use problematic dyes and colorants that can contaminate whole recycling streams.

On the social and cultural side, one of the most fundamental challenges that all societal transitions face lies in changing the behavior and mindset of people: their willingess to participate in recycling programs and in the development of new, circular business. The transition to a circular economy will require a great deal of new skills and knowledge: a whole new workforce of people trained to remanufacture products and reuse materials in different ways.

The financial part of change management can sometimes be challenging. Currently, most recyclables have low value – in many cases, because of high levels of contamination among the collected resource streams. A bale of pure PET bottles has much higher value than a bale of mixed plastic, for instance. It is essential to work actively with the market to develop solid business cases for circular resource management.

There are, finally, a number of political and legal barriers. One of these is the solid waste interlocal agreement between Charlotte and Mecklenburg County, which currently dictates how all of Charlotte’s waste is handled after collection. On the day-to-day level, existing rules and regulations can hamper how certain waste streams are used and where certain activities (for example, food production) can take place.

Actions

Charlotte’s transformation to a circular city clearly cannot take place overnight. Near term actions should focus on building awareness among the city’s citizens, business owners, and other key stakeholders on what the circular economy is and the different opportunities it can provide as well as laying the groundwork for tackling some of the barriers we identified.

In addition, it is essential to identify tangible actions, showcases, and circular business cases that can be executed quickly in order to build support for the approach and demonstrate its value. Further steps should include capacity building and efforts geared at longer-term transformation, such as neighborhood action plans, the establishment of new partnerships and institutions, and monitoring programs to track the city’s progress on circular economy metrics (i.e., the KPIs presented in Chapter 2). A short, mid, and long-term set of activities that Charlotte should undertake are presented in the roadmap in Chapter 4. We have divided near-term actions that the city should take into several categories:

- Establishing public sector commitment and developing a circular economy strategy

- Launching a communications strategy and developing the Innovation Barn as the city’s local circular economy showcase and innovation center

- Building Circular Charlotte’s international profile

- Creating circular economy programs for the city and securing long-term staffing and financing

- Building circular infrastructure and resources

- Establishing the basis for data collection and performance monitoring

Next Steps

In addition to actions that the city should take in the near term, we have summarized some of the steps that other groups of stakeholders (such as funders, commercial and industrial sectors, NGOs, and knowledge institutes) can take in a coordinated effort towards achieving a circular economy (see Chapter 6).

The initial groundwork for the circular transition, however, should be laid by the government. The city has already demonstrated its public sector commitment to a circular economy. Now this must be communicated to the local community and made tangible. The Innovation Barn can become one of the first meeting places and centers for activity and learning on this topic, kicking off the start of this shared journey.

01 Circular Transformation in Charlotte

Introduction

Nearly every turn you take as you walk through Charlotte’s Uptown greets you with a new construction project of impressive scale. The city is in the middle of a building boom, adding everything from apartments to office buildings and hotels. While Uptown is sprouting expansions to its sleek skyline, neighborhoods like NoDa, a historic district once at the center of the city’s textile manufacturing industry, are bursting with the addition of new microbreweries, restaurants, and arts venues.

This expansion of the city points to Charlotte’s increasing popularity as a place to live and work. Charlotte is now ranked as one of the fastest growing metropolitan regions in the United States (7th out of 53), having increased in population by 13.9% between 2010 and 2017 (Thomas, 2018). Importantly, Charlotte was recently named the number one city for attracting millennials, demonstrating its position as a place of opportunity for launching a career and building a family (Abadi, 2017).

Beyond changing physically, Charlotte is undergoing a broader transformation in its character, evolving from a banking-focused city with a history of manufacturing and logistics, to a dynamic urban center with unique specialties in the high-tech industry. Though it is currently ranked as a “gamma-minus” city – the lowest tier on the Global Economic Power Index (GEPI, 2015) – these transformations position Charlotte to become more of a force in the international scene over the coming years.

With every new building and enterprise taking root in Charlotte, the city has a chance to reimagine its future and shape the values and principles that will define the next phase of its history. This growth is not only an opportunity to cash in on Charlotte’s successes, but also to address challenges – those specific to Charlotte, and those we face as humanity at large. Investment brings with it the opportunity for creativity and innovation – as well as the development of new solutions that can become the basis for Charlotte’s next wave of prosperity.

Building an inclusive, zero-waste economy

One of the largest challenges that Charlotte faces was highlighted in a now widely-cited study, published by the Equality of Opportunity Project, which examined economic mobility in America’s 50 largest cities. With only 4% of people born into poor families in Charlotte successfully making it out of poverty in their lifetimes, Charlotte’s performance was ranked last out of the cities evaluated (Chetty, 2017). Though the problem of low economic mobility is clearly severe in Charlotte, it is a challenge that many cities and countries around the world face.

The city’s current phase of growth must therefore not only improve overall wealth: it must provide pathways for decreasing income inequality and increasing access to opportunity for all.

Devising structural solutions to these problems will not only benefit Charlotte, but potentially serve as an example to other parts of the world facing similar struggles.

This period of development also gives Charlotte space to take action on another key opportunity and moral imperative: the transition from a linear to a circular economy. The vast majority of our economic system can currently be defined as linear. We extract resources, use great amounts of labor, energy, and money to transform these into products, and then, soon after their use, these products get thrown away. Every time a product that we have crafted and manufactured with care ends up in a landfill, we lose its “embodied value.” McKinsey estimated that up to 630 billion dollars a year are lost in Europe through the loss of materials in the linear economy (EMF & McKinsey, 2011).

This linear system is not only generating an enormous amount of waste and loss of value: it is also putting our way of life at risk. Certain critical resources, like the metals used in electronics, are becoming scarcer. The ecosystems that we rely on for essential environmental services (like the production of clean air and water), as well as the supply of goods (from food to building materials), are overexploited and at the point of collapse. As our economy continues to grow, our demand for these already overexploited materials continues to increase, exacerbating these issues. We need to transition to a smarter model of resource management, where instead of getting lost, these valuable materials are kept in perpetual circulation, reducing the need for increasingly scarce or hard-to-extract virgin materials.

Our dominant economic model, though it has historically brought much prosperity, has now reached a point of diminishing returns.

Though it continues to generate value and prosperity, it does so at the expense of an increasing socio-economic divide and contributes to the destruction of natural capital that is essential for its own continuation. The circular economy – a new economic system that is regenerative and waste-free by design – can not only eliminate negative impacts and create new sources of value, but can also be used to bridge the wealth divide and create new pathways for upward mobility in Charlotte.

Within a circular economy, products and materials are circulated at high value for as long as possible, extending the life of products and enabling high-value component and material recovery for reuse or recycling. The systemic transformations involved in a circular economy – from the development of new technologies, to the evolution of new forms of collaboration and new business models – have also been shown to have great potential in generating new employment and skill development opportunities.

Circular Charlotte

Charlotte is the first city in the United States to make a commitment to adopting the circular economy as a public sector strategy. In its circular future, all of the material resources that now end up in landfills will be the basis for Charlotte’s next industrial revolution: the foundation for an era of green manufacturing that unlocks new technological advances and increases local resilience and productivity.

This study, commissioned by the city of Charlotte and Envision Charlotte, helps lay the groundwork for the city’s transition to circularity. In it, we describe the results of a baseline analysis of Charlotte’s current circular economy performance, including the total value of resources wasted in the city. Together with inputs from stakeholders throughout the city, we have drafted a vision statement for what a circular Charlotte could look like, and created a set of metrics – Key Performance Indicators – that can be used to track the city’s progress. Lastly, we present an initial roadmap and a selection of high-impact business cases that can already be implemented within the city in order to move towards a circular economy.

The results presented here are just the first step in a long journey. Though the first step is often the hardest, it is also the most important: it signals a commitment to move towards a greener, healthier, and more equitable future for Charlotte and its people.

The city of Charlotte

The city of Charlotte, known as the Queen City after its eponymous German princess, Charlotte of Mecklenburg-Strelitz, was incorporated in 1768 and settled by an initial wave of Irish migrants. Though the basic grid network of Charlotte’s Uptown was already laid out by surveyors in 1770 in anticipation of further development, at that point the town only consisted of a handful of log houses.

In 1799, gold was struck in nearby Cabarrus County, setting off the first American gold rush and making North Carolina the leading state for gold production until the opening of mines in the western states. As more veins of the precious metal were discovered, the Charlotte Mint was founded to locally melt and coin the gold. Despite these developments, Charlotte remained a relatively small town, and only experienced its first significant growth phase after the Civil War, when a combination of factors led to Charlotte’s emergence as one of the South’s primary centers of activity.

Financed by prominent Charlotte-area businessmen, the Charlotte and South Carolina Railroad began operating in 1852. This line played a critical role in the emergence of Charlotte’s textile boom in the late 19th and early 20th century, when the city became a watershed for cotton produced in North Carolina and neighboring states. Cotton mills sprung up throughout the city and workers flooded in to process the material into new high quality products such as textiles, clothing, and furniture. To support this new boom in commerce, logistical connectivity continued to improve, making Charlotte into one of the most well-connected hubs in the country. In 1910, Charlotte surpassed Wilmington to become the largest city in North Carolina, reaching a population of 34,000.

Pioneering character

Charlotte’s prosperity has historically been driven by a spirit of risk-taking and innovation, informed by the acuity of its people in paying attention to the technological trends of the time. While other neighboring towns rejected the idea of having a railroad because it would be too noisy and polluting, Charlotte embraced this leap into the future. The drive to stay on top of the latest trends began with Charlotte’s railroad and first cotton mills and continues into today’s aerospace and electronics manufacturing industry.

While other cities have struggled, and buckled, under the pressure to outsource their local industries, Charlotte has maintained and diversified its existing capacity and infrastructure. Today, manufacturing represents about 30% of the regional economy and employs 144,000 of Charlotte’s citizens (Charlotte Chamber, 2015). With the presence of some of the world’s biggest furniture and textile companies, traditional manufacturing is still going strong in Charlotte, but the city has continued to diversify and enhance its capabilities in areas such as energy technology, aerospace technology, precision metrology, and specialty chemicals and plastics.

Charlotte’s industrial success has translated to high levels of prosperity. The city is ranked 7th on Forbes’ list of Places For Business And Career, has an average household income of $56,731 (Forbes, 2018), and an unemployment rate below state average at 3.4% (Bureau of Labor Statistics, 2018 – April). Across various metrics, Charlotte is doing significantly better than other cities in the same weight class.

Partly resulting from this prosperity, Charlotte developed another major role as a prominent banking center in the 1970s and 80s. The city is home to the headquarters of Bank of America, and to the secondary headquarters of other major banks like Wells Fargo, making Charlotte one of the largest centers of banking activity in the United States, second to only New York City (Roberts & Rothacker, 2017).

As evidenced by the current construction boom, Charlotte has become a popular destination for young and highly educated professionals looking for a place to advance their careers (Fahey, 2016), and has been recognized for its high quality of life and livability (Stebbins, Comen, & Sauter, 2017).

Charlotte: A great place to be

- Attractive to businesses: 7th on Forbes list of Places for Business and Career (Forbes, 2018)

- Job opportunities: Unemployment below state average at 3.4% (Bureau of Labor Statistics, 2018)

- Wealthy: $53,000 GMP (global metropolitan product) per capita – 61st wealthiest metro (Parilla, 2016)

- Livable: 26th most livable city in US (24/7 Wall St., 2017)

- Hotspot for young people: Number one choice for millennials in 2015 (Abadi, 2017)

- Clean: Among the least polluted cities in US (American Lung Association)

The Strengths of Charlotte

- Specialized in advanced industry: 7th in growth of advanced industry from 2013 to 2015 (Mecklenburg County Community, 2018) – 8.9% of Charlotte’s workforce is employed in advanced industries (2014) contributing to 17% of GMP

- Strong manufacturing sector: The manufacturing industry represents about 30% of the regional economy and employs 144,000 citizens in Charlotte (Charlottechamber, 2015)

- STEM jobs: The Charlotte metro has a high demand for STEM occupations, especially in middle-skill jobs, helping maintain attractiveness for workers (Parilla, 2016)

- Globalized economy: 14% of GMP in 2014 provided through export (110,000 jobs in Charlotte supported by export) and 6.8% employment at global firms

- Well connected: 45 million passengers per year in Charlotte Douglas International Airport, placing it 24th globally. 27,000 miles of rail connects Charlotte with 23 states

Areas for improvement

In the midst of this account of Charlotte’s successes, there is another story that until recently remained largely untold. Despite being a wealthy city with a generally high quality of life, Charlotte has more than 148,000 people living in poverty (DATA USA, 2018). In several neighborhoods, more than half of the residents are living below the poverty line (Off, 2016). Looking at a map of Charlotte’s average income per neighborhood shows how dominant this social divide is in the city’s geography, marking a physical rift across the city. Combined with the recent findings on Charlotte’s low social mobility (Deruy & Boschma, 2016), this paints a picture of a city where 13.4% of the population is currently left behind. Tensions resulting from this social divide have justifiably added to local discontentment, and can be linked to events such as the riot of 2016, which put Charlotte in the international media spotlight.

Another barrier to Charlotte’s development has to do with demand for highly skilled labor in science, technology, engineering, and mathematics (STEM) fields. There are not enough local graduates with these skills to fill local demand. This makes Charlotte attractive for graduates from other parts of the country, but can also slow down tech development as these hiring needs go unfulfilled for longer periods of time (Parilla, 2016). Potentially connected to this low number of STEM graduates is the fact that Charlotte is lagging behind on key metrics related to innovation and new business, as highlighted below:

- Lowest social mobility among the 50 biggest cities in the US (Deruy & Boschma, 2016)

- More than 148,000 people living in poverty (DATA USA, 2018)

- Shrinking middle class (Mecklenburg County Community, 2018)

- Low investment in R&D – behind similar cities with a factor 20 or more (Parilla, 2016)

- Patenting is increasing but still below other cities (Parilla, 2016)

- 25th out of 40 in Kauffman Foundation 2015 Startup Activity Index

- Lower amount of venture capital compared to other cities

- Not enough local graduates to support local demand for educated labor – a large share of employment is covered by immigrating graduates (Parilla, 2016)

The path ahead

Charlotte clearly has the wind in its sails and is poised for continued growth. However, to genuinely seize the opportunity to become a more visible participant in the international community of cities, it still needs to tackle some central challenges, among which, we identify:

- Creating a unique and progressive brand for the city and its business environment to consolidate its position as a city of the future.

- Improving the resilience and livability of the city to continuously make it a safe and attractive home for its citizens.

- Closing the social divide and formulating a vision for the city that unites all social groups.

- Becoming an international example of how economic and industrial development can progress in a sustainable and circular manner.

- A pathway forward that can address all of these issues is the transition a circular economy.

The Circular Economy

We now live in what has been described as a linear economy, where we extract many biotic (e.g. plant or animal) and abiotic (e.g. mineral or metal) resources, use them, and then send them to a landfill or disperse them into the environment in a way that they are unrecoverable – for example, through incineration, spraying of chemicals, or the use of products like paints that are not designed for recovery. Less than 10% of the materials that pass through our economy each year are recycled (Haas, Krausmann, Wiederhofer & Heinz, 2015).

Moving towards a “circular economy,” which is broadly defined as an economy that is regenerative and waste-free by design, presents vast potential for financial gains made possible through the reuse of all raw materials that are currently lost in the linear “take, make, dispose” system and by extending the value-generating life cycle of products. This transition can be supported through alternative business models and purchasing patterns that will structurally support the recovery of materials, such as leasing models and advanced approaches to extended producer responsibility (systems that make product manufacturers responsible for what they create and sell, even after the products are sold).

Preserving complexity yields more value

One of the principles of the circular economy is to preserve complexity to the greatest extent possible. As illustrated in Figure 2, the value of a product is much higher than the value of its individual parts, and the parts are much more valuable than the base materials they are made of. In an ideally circular system, products are designed for easy repair and refurbishment, so they can go through multiple cycles of use before they need to be taken apart. Once they can no longer be repaired, products should ideally be designed for disassembly, making it possible to harvest their components for high-value resale. Finally, when no more value can be extracted for these elements, all materials should be recycled at high quality (without mixing or downgrading them to lower uses).

A parallel to this value cycle can be seen in the amount of employment generated through circular practices at different levels. The US EPA and the Institute for Local Self Reliance estimate that low-value activities that result in material losses (like incineration and landfilling), only generate a handful of jobs per 10,000 tons of used goods. Recycling generates an order of magnitude more, but reuse and refurbishment are by far the winners, with almost 300 jobs created.

Implementing a Circular Economy

Though there are many definitions of the circular economy (a recent literature review looked at 114 variations), there are some core traits that most people think of when they hear the phrase. Often, we use analogies with natural systems to explain how such an economy could look: when you’re walking through a forest, there is no real “waste” generated. There may be leaves on the ground or fungi feasting on fallen trees, but everything is part of a cycle that reabsorbs these resources back into high-value use. The basic principles of designing an economic system based on this model initially seem straightforward, and include:

- Design all products for easy repair, disassembly, and full recyclability.

- Create the necessary business structures and incentives to get these materials back into the economy at their highest possible value (preferably as whole products or components).

- Strive to use only responsibly-sourced renewable resources for both energy and material provision.

- Avoid the use of toxic substances that may continue to circulate in our environment.

When applying this circular approach our own economy, however, we quickly run into the realization that not all options for closed-cycle resource management result in an optimal outcomes. If we use more oil to recycle plastic bottles than we would use to create new bottles, this is not a circular solution. If we overharvest available natural resources, leading to the destruction of ecological productivity in our agricultural landscapes, likewise, we have damaged the regenerative basis on which our ideally regenerative circular economy should rest. Furthermore, if our recycling practices are dangerous and lead to health impacts for individuals, then the fundamental point of the system, which is to facilitate a healthy and equitable society for all, is called into question.

Therefore, there are several other parameters we need to consider when aiming for circularity. Yes: we want to manage our resources so that they can cycle infinitely at high value. But: we must do so without undermining our natural capital, creating stresses on Earth systems like the climate, leading to social inequities, or threatening the health and wellbeing of humans and other animals. Therefore, from an integrated perspective, a circular economy is one where we maximize the value generated from resource cycles without undermining the functioning of the biosphere or the integrity of human societies. Activities in the economy should be therefore judged on how well they support this ultimate outcome.

The circular economy is a new economic model for addressing human needs and fairly distributing resources without undermining the functioning of the biosphere or crossing any planetary boundaries.

Seven Pillars of the Circular Economy

Figure 4 illustrates Metabolic’s “seven pillars” framework for evaluating circularity. These seven pillars capture the areas that must be simultaneously considered when looking at whether certain activities are genuinely circular. We need to evaluate all of our actions not just on one parameter, but on a complete spectrum. With a holistic set of performance indicators, we can track whether or not circular activities are leading to better results across a broad range of impacts, rather than just optimizing for high value material recovery at the expense of other areas of performance.

To achieve real progress towards a circular economy, it is clear that we need new incentive structures, new business models, and new ways of evaluating our economy to assess whether it is functioning within the safe limits of Earth’s carrying capacity. By shifting from the current linear economy to the circular is fundamentally difficult as it challenges many structures and mindsets that are considered common sense but it also holds the potential to unlock formerly wasted value and spark new innovative solutions. Most importantly, the circular economy offers a way to structure the economy in such a way that it can continue to prosper well into the new century as resources are getting scarcer and demands continue to rise.

02 Vision for a Circular Charlotte

Developing a circular vision

If we take these high level ideas about the circular economy and actually apply them to Charlotte, what might the city actually look like in a circular state? Here we envision some of the changes that might take place within Charlotte if it achieves the full spectrum of a circular economy. We have organized the vision around four thematic areas:

Though some of these ideas may seem farther off in the future than others, every plan starts with imagining the reality we aim to achieve. The picture we describe here, from a 2050 perspective, will certainly not be a perfect reflection of what actually transpires, but it can provide a starting narrative and inspiration for the next decades of Charlotte’s development.

1. Charlotte as a Zero Waste City

In 2050, Charlotte can proudly call itself a Zero Waste City. Back in 2018, when the Charlotte set off on its transition path, less than 12% of its solid waste was recycled or composted – and many of the recycling methods used at that time would not even qualify as recycling today. The majority of the city’s solid resources were put into low-value applications (i.e., downcycled), like cement being used as road-filler.

Today, 98% of all residual materials are separately collected, and only the 5% of waste that is too low quality or hazardous to otherwise process is incinerated for energy recovery. The incineration facility opened in 2029, just a couple of years before Charlotte celebrated the permanent closure of its landfill, which ceased operating because the volumes of waste were too low. The small incinerator has been built to such high emissions standards that the air it releases is even cleaner than the ambient air. The amount of hazardous waste generated in the city is still decreasing each year as old stocks of products are slowly replaced with ones that have been designed based on circular principles.

Throughout the city, each household is equipped with smart sorting containers that simplify the process of separating different materials. The containers’ built-in technologies tell users if they have sorted something incorrectly. However, the incentive to properly sort resources is already very high: for every pound of correctly sorted waste, residents get Charlotte Coins paid directly into their digital wallets. They can use their earnings for the purchase of local goods branded with the Circular Charlotte label, many of which have been remanufactured or grown from those same residual streams. If they have Charlotte Coins left over, they can also use them to pay for their – fully renewable – energy bill, or even pay their taxes.

A real-time resource monitoring platform, the Charlotte Circularity Dashboard, continuously reports how much is available of different kinds of residual goods – from citrus peels to old shoes. These resources are automatically diverted to various processing facilities throughout the city, run by large companies and small entrepreneurs alike. The Dashboard keeps a record of orders placed requesting different materials, and ships off materials to the earliest bidders. Because of Charlotte’s strong position as a logistics hub, the city also accepts and processes many materials from the nearby counties, adding to the base of resources used for local manufacturing.

But before anything is ever disposed of in Charlotte, it gets the royal treatment of repair and refurbishment, maximizing its usable lifespan. The Innovation Barn, the city’s center for circular innovation, is one of the busiest places in the city, with cafes serving food from the building’s greenhouses, and with many different stores featuring upcycled products. It is also a center for experimentation and education, with many specialized repair facilities and workshops. New circular ideas are piloted at The Barn, and then scaled up in many other parts of the city. The Barn has also led to a completely different social dynamic than existed in the 2010s, when the main options available for spending time with friends involved eating or drinking at a café or bar. People come to the Barn to learn new skills, but also to socialize while repairing their own clothes or trading their old furniture in for something new.

2. Charlotte as an innovative city of the future

With Charlotte’s innovations in waste collection and sorting, which resulted in the supply of previously-unavailable high-quality and pure resource streams, a whole new cluster of industries began to develop throughout the city. New product development exploded in the early 2020s. At first, the major focus of R&D activities was on processing textiles, plastics, and construction wastes. In 2023, CharM, the city’s newly opened materials lab, a joint project of several of Charlotte’s incubators and accelerators, began experimenting on how to convert collected bio-wastes into new materials – like clothing, furnishings, and biodegradable packaging.

Later, it became clear that complex consumer goods like household appliances could also generate more value in this new economy. Manufacturers discovered that they could actually claim financial benefits for every pound of materials that was successfully harvested from their products – provided that they included an RFID tag that could be scanned at the automatic sorting and disassembly unit newly installed at the city’s Materials Recovery Facility (MRF).

The strong need for materials and product innovation because of the city’s ambitious circularity goals also led the University of North Carolina Charlotte to establish a new educational facility, the Charlotte Institute of Circular Design and Engineering (CICDE). CICDE is now one of the top engineering schools in the world, attracting the brightest minds from throughout the U.S. and abroad. Charlotte is now broadly recognized as one of the world’s most innovative design centers, and has pioneered the emergence of circular products that are now dominant in global supply chains.

As engineering and design became a central part of Charlotte’s higher education scene, primary and high school curricula were updated to include more experiential learning opportunities and a unique mentorship program that paired up students with researchers. Most high school students now go through an internship at one of the many tech companies in Charlotte’s burgeoning startup scene.

These new industries have transformed Charlotte’s local economy, creating thousands of new jobs, boosting the city’s resilience, and serving as an example for other cities around the world. The Circular Charlotte brand helped the city consolidate its leading position globally, and cemented Charlotte’s top position in global rankings such as the Sustainable Cities Index. Barely a week passes without an international delegation coming to visit the city and learn from its successes.

3. Charlotte as a resilient and healthy city

Back in 2018, at the start of Charlotte’s transition to circularity, North Carolina was importing a net value of 47.4 million dollars’ worth of commodities each year. China had just closed its borders to lower-quality recyclables, leaving countries around the world struggling with the challenge of processing huge volumes of unwanted material. The drive for innovating towards circularity was not just a matter of principle: it was equally grounded in economic opportunity and the need for greater local resilience.

Since circular building standards became the norm, new buildings in Charlotte are designed for complete disassembly. They are demolished by highly trained demolition teams with the help of efficient robots, who scan all individual building components and register them on the Charlotte Circularity Dashboard. The city is now able to harvest a large fraction of the materials needed for new construction projects from within its own demolition cycle, and has in this way eliminated around 30% of the material that used to go to landfills.

As other circular industries developed, Charlotte and its surrounding region became increasingly independent of foreign imports, with almost all material sourced from local cycles. Even local food production has grown immensely, with the advancement of vertical farming technology and the reuse of organic waste streams as fertilizer. Most of Charlotte’s schools now also have their own small-scale aquaponics facilities, which are used both for hands-on science education as well as to provide farm fresh produce and fish to the schools’ cafeterias. Further efforts to increase the city’s health and resilience have focused on the decentralization of certain utility services. Renewable energy, decentralized battery storage, and smart distribution of energy through the city’s smart grid have made Charlotte’s energy system highly resistant to the impact of storms or floods, with most damage remaining localized.

Circular Charlotte also became dramatically greener as nature-based solutions became an increasingly central element in the design of buildings and public places. The most dramatic change only happened recently, in 2037, when the municipality finally did away with all personal vehicle transport in the inner city. All the asphalt roads were converted into green boulevards, with walkways meandering among trees and flowers, lined with miles of well-connected bike paths. At the center of each boulevard are rail-lines for the public transport vehicles, which can be ordered on command from any part of the city. They are driverless and each have several seating compartments, allowing people to be picked up and delivered efficiently to their final destination. The parking lots which once dominated Charlotte’s Uptown have all been replaced with either public green spaces or new mixed-use developments, further improving the walkability and “human-scale” of this busiest part of the city. People’s overall health has improved as a natural result of more walking and biking, not to mention the drastically improved air quality. The city’s canopy of trees, which was under threat in 2018 due to increased tree removal relative to new planting, has never been as dense as it is today. Charlotte is one of the greenest cities in the US, known to some as an example of an urban forest.

4. Charlotte as a city with opportunities for all

Though Charlotte now has less than 0.5% of its population living in poverty, at the start of its journey towards a circular economy, this was far from the case. For this reason, initial efforts on establishing circular industry and innovation were largely focused on skill development, training, and inclusive programs designed to lift up those who were economically disadvantaged.

In 2019, the city’s solid waste department established a test rehabilitation program for the homeless community, providing employment in plastic waste sorting and remanufacturing. Plastic wastes, which were of too low a quality for automated processing at that time, were sorted, washed, and shredded for the production of small batches of local products like street furniture, waste bins, and trophies for school sporting events. Some of trainees involved in the pilot program went on to start their own companies focused on recycling and product manufacturing.

In a similar effort, local culinary schools, like the Community Culinary School of Charlotte and the Culinary Program at the Art Institute of Charlotte, collaborated to set up a program focused on the establishment of circular businesses in the food sector. Successful projects resulting from this effort include a 5-star restaurant that uses food salvaged daily from grocery stores to produce gourmet meals, a farm-restaurant hybrid where all food served is produced on site in vertical agriculture systems, and a food processors cooperative making soups, sauces, and jams out of produce rejected at retail stores because it failed to meet aesthetic rather than safety standards.

From the very start of Charlotte’s shift towards a circular economy, the Goodwill Opportunity Campus, already a community fixture, has played an essential role in mainstreaming and supporting circularity efforts. In 2019, the Campus, launched a new range of circular training programs focused on repair and remanufacturing skills, which resulted in a slew of new store openings and services within the city. In addition, the Charlotte Chamber of Commerce launched support services for new entrepreneurs and local makers, giving advice and providing resources for people launching businesses. All local products made or refurbished according to circular principles can be labeled with the Circular Charlotte brand, which has been an important marketing platform for small enterprises in the city, particularly in their early stages.

Another effort towards improving quality of life and increasing access to opportunities has been the development of circular housing in Charlotte. As part of the housing boom of the 2020s, the city of Charlotte began to encourage inclusive development by giving priority to developers who aimed to include different price levels of housing within individual developments. Not only did this effort increase the social cohesion of neighborhoods, as young couples were able to stay in their neighborhood as their income levels rose, but it also created an equitable manner of providing lower-income housing in prime locations throughout the city.

A uniquely circular feature of many of the new housing developments was the emergence of “full service living” concepts. When you rent or buy a house, you can select from a range of equipment, furniture, and transport packages – like access to cars or bikes, giving you permanent access to the most efficient and up-to-date appliances and equipment. The companies providing this equipment get a steady income stream from the rental of their products, but also have the incentive to design these products for refurbishment and recycling, since they remain responsible for the full lifecycle of their equipment. The new full-service housing concepts have reduced the total amount of large household goods thrown out in the city, and has made moving – especially for students and people starting out their careers – much more carefree.

Measuring Circularity

The vision imagined in the previous section shows one of many ways that Charlotte could develop as it progresses towards a circular economy. Regardless of the exact path that the city and its residents choose to travel, there are certain performance outcomes (like eliminating waste sent to landfill) that should ultimately be achieved in a circular model. To help understand these performance outcomes, and make the transition to circularity tangible and actionable, we have translated the vision into concrete goals and key performance indicators (KPIs) that can be used to measure Charlotte’s progress towards circularity. As with the vision itself, these must be holistic and cover not only the physical reality of achieving circularity (resource cycling, impact reduction, etc), but also cover the auxiliary benefits of circular activities (such as employment, innovation, and health) to ensure that the strategy is implemented in a way that also increases value and equity for society.

These goals and KPIs have been developed based largely on inputs from the City of Charlotte and other stakeholders over the course of two stakeholder sessions. They are organized across the same four thematic areas that we have used to define the vision for a Circular Charlotte.

On May 24th, we hosted a stakeholder workshop with entrepreneurs, universities, city representatives, etc. to understand community priorities on moving towards a circular economy and to help shape the vision for a Circular Charlotte.

To illustrate the holistic nature of the goals and KPIs, the KPIs are linked to our seven pillars of the circular economy framework (plus three overarching categories), which is described on page 13. The following legend shows the icons used to represent each of the pillars and overarching categories.

1. Charlotte as a Zero Waste City

Highlighted KPI

2. Charlotte as an innovative city of the future

Highlighted KPI

3. Charlotte as a resilient and healthy city

Highlighted KPI

4. Charlotte as a city with opportunities for all

Highlighted KPI

03 How circular is Charlotte?

Understanding the current state

In order to create an effective strategy for Charlotte around the circular economy, we started by first building an understanding of the way things are currently functioning through a baseline assessment of the context, stakeholders, waste flows, and economic and social potential of wastes. This chapter provides an overview of the results from this first baseline assessment as a starting point.

The economic and environmental outcomes we see in Charlotte result from the structures (e.g. social, economic, political, physical) and the actors working in Charlotte. In the first two sections of this chapter, we provide a bit of background on the story of waste in Charlotte, looking at the context and the stakeholders active in the city.

This is followed by a material flow analysis, which provides a big picture view of where a large share of the wastes in Charlotte are coming from, what they consist of, and what is happening to them (e.g. landfill vs. recycling or composting). As we collected data to map out and understand these material flows, we also identified a number of hotspots (or problem areas) and opportunities, which are highlighted in this section.

Finally, we did a quick economic assessment on the material flows that are currently going to landfill. We looked at two basic scenarios: waste incineration with energy recovery and simple recycling material value. For each scenario we looked at the revenue and jobs potential of diverting this waste from landfill.

It is important to note that these options are not yet “circularity strategies”, as these only look at the residual market value of the materials themselves. A circular strategy would involve examining the full value chain (e.g. materials should be designed for recovery when they are first produced) and the structural prerequisites required for circularity. Truly circular options offer the possibility of recovering far more value than simply looking at the market value of residual waste streams. Additionally, this is not yet an assessment of profit potential, as we only look at the lost revenue potential heading to landfill (and not the costs). These issues are covered in the following chapters on strategies and specific business cases.

Exploring the context

How the waste system functions in Charlotte

For a typical household, involvement in Charlotte’s waste system includes weekly curbside pickup of municipal solid waste, biweekly pickup of recyclables, and occasional trips to drop-off centers or other locations to bring types of waste not collected at home. The costs of the program are covered by property tax fees paid to both the city and the county ($63 dollars in total) as well as other sources, such as special waste fees (for tires, white goods, etc) and the sale of recyclables. These costs are not differentiated by household size, the amount of waste (or recyclables), or income.

In the curbside recycling program, the city collects paper and cardboard (including paper cans and pizza boxes), plastics #1-5 and #7, milk and juice cartons and boxes, aluminum and aerosol cans, and glass bottles and jars in a single container. This system has been in place since 2010; before this, households had to separate paper products from other recyclables. While the new system solves logistical challenges (for example, fewer trucks are required), it also translates to a higher level of contamination and lower-quality recyclables.

Overall, recycling participation rates are low in Charlotte (53%), which is lower than other parts of Mecklenburg County (Mecklenburg County Residential Recycling Behavior 2009 Observation Study, 2009). Since 2009, in the state of North Carolina it has been technically illegal to landfill HDPE and PET (Granger, 2009), though there are no frameworks in place to prevent households from placing these materials in the municipal solid waste bins, resulting in a large share of these materials ending up in the landfill anyway.

If households would like to recycle batteries, light bulbs, textiles, hazardous waste, construction materials, electronics/appliances, oils, or tires, plastic bags, or other metals (like wire hangers, pots and pans), these must be taken to retailers or the county-operated drop-off centers in Charlotte. While the drop-off centers were originally established with the main purpose of collection of household recyclables, the majority of the waste by mass brought to the facility is bulky and construction waste from contractors and cardboard (which can be recycled in curbside programs).

Weekly use across all self-service drop-off centers was estimated to be roughly 800 visitors, of which 88% were households. This means that only 0.2% of the County’s households are using the centers each week. For the roughly 19,000 households in Charlotte without a car (Governing the States and Localities, 2016), making a special trip to a drop-off center is practically infeasible, while it is also inconvenient for those with a car. Just the same, drop-off centers have been overcrowded, often with lines. This is due to the fast population growth of Charlotte (+30% over the past decade), resulting in too little capacity in peak hours (DSM Environmental Services Inc., 2017)

The city and county have no means for taking and recycling #6 plastics (including styrofoam), plastic dinnerware/cutlery, aluminum or plastic foils and wraps, non packaging glass (glassware, plate glass), diapers, or ceramics. Therefore, these materials are added to the residual waste bins.

For the majority of companies and other organizations located in Charlotte, the city and county does not provide waste collection and handling services. These organizations must handle waste themselves (for example contractors taking waste directly to landfills or drop-off centers) or establish a contract with a waste hauler. Larger haulers operate their own material recovery facilities for recycled materials or have partnerships with recyclers, making it cheaper to process recycling than general solid waste (with high tipping fees for landfilling). This provides a good incentive for companies and waste haulers to strive for more ambitious recycling rates.

Mecklenburg County is responsible for operating the material recovery facility (MRF) where household recyclables end up. At this facility, recyclables are separated and baled and sold on to third parties. Lately, with the Chinese ban on imports of recyclables of a low quality, finding an appropriate market for these materials has become more challenging, resulting in an accumulation of recyclables.

Charlotte has a large number of recyclers operating in the region, processing everything from plastics to electronics, though much of the material these companies are processing is post-industrial or imported waste rather than regional post-consumer waste. The main reason for this is that regional post-consumer waste is largely too contaminated, with impurities and other materials mixed into the loads.

With export markets disrupted by the Chinese ban, there may be further incentive now to upgrade the quality of recyclable materials locally (for example through washing and shredding), which could benefit local recyclers and increase employment in the local recycling sector. In North Carolina, it has been shown that increased recyling leads to far more jobs created than lost in industries such as timber harvesting and waste disposal (Institute for Local Self-Reliance, 2002).

Current initiatives in Charlotte

Though there is a new wave of momentum behind the circular economy, there are already many initiatives in Charlotte that can already be described as circular.

For example, the city established the Healthy Communities program to divert waste from landfill and increase composting and recycling by educating locals. In 2016, around 6,600 citizens were reached through events to provide information on waste separation. In 2017, the city won the Excellence Award for Innovation in Communication, Education and Marketing for the program from the Solid Waste Association of North America. Solid Waste Services is planning on continuing this program to reach more households over the coming years.

As Charlotte strives to become a zero-waste city, there will still be a number of landfills in the region that will need to be remediated. In Mecklenburg County alone, there are eight heavily-polluted landfills that were put into place when environmental regulations were less stringent. There is already precedent in Charlotte for how to make use of these landfills. The Double Oaks landfill was cleaned up with an investment of $2.1 million and is now a play area and park. In 2016, Charlotte approved a plan to convert another old, polluted landfill site into a solar farm to produce 2-3 MW of electricity (Henderson, 2017).

In addition to these city-level programs and projects, there are a number of entrepreneurs working on interesting initiatives. A few examples, include:

Crown Town Compost – Not everyone in Charlotte has the opportunity for at-home composting and although there were collection programs for yard waste, there was no program to handle the food waste going to landfill from households. Crown Town Compost was established to collect food waste from households and restaurants in a weekly collection program. While this food waste is currently composted with Earth Farm Organics, Crown Town is looking for alternative ways to handle food waste as the program scales up further.

Habitat for Humanity ReStores – Habitat for Humanity is a charity organization that mobilizes volunteers and funding to build houses for families with low incomes who otherwise could not afford to own their own homes. The ReStores are thrift stores for secondhand building and household materials (such as lighting fixtures, cabinetry, furniture, wood, etc). The ReStores divert waste from landfill as well as providing income to fund the Habitat for Humanity program.

Goodwill’s Opportunity Campus – A new project established to provide a learning center for teaching people who struggle to find work new skills to get them into the workforce. In addition to the educational programs and two thrift stores on site, the campus also includes a garden for food production. The food is served in the cafe on-site, which also serves to teach people new cooking skills.

100 Gardens – An educational program that aims to teach students about science, technology, business, marketing, and much more through operating aquaponics labs (hydroponic greenhouse production combined with fish production in a symbiotic system). So far, ten labs have been established in Charlotte schools to provide students with a hands-on way of learning about how natural systems function, while also inspiring kids to learn about technology and applied sciences.

How the waste system looks spatially

Charlotte has some areas of the city with extreme poverty and high unemployment rates of up to 50%. We wanted to see if waste collection or processing areas correlated with these areas of economic strife. The southern part of the city, forming a wedge that starts at the center, has a significantly higher median income than the rest of the city. This whole area also only has one recycling center placed on its far southern part and no landfill. At the same time, the lower income areas in the Northern part of the city center have several recycling centers.

This distribution has of course happened organically as the city has developed, but at this point it may form a logistical challenge that makes it more costly to increase the separation capacity because more trucks will have go back and forth to this wealthier area. For residents in the wealthier areas it may be more cumbersome to visit recycling centers, while residents in low-income areas may experience the noise and air pollution of recycling centers, landfills, or trucks traveling to these as a nuisance in their neighborhood.

Mapping the stakeholders

In Charlotte there are a large number of stakeholders involved in the waste system, including the waste generators (which involves more than 300,000 households and over 60,000 companies and other organizations), waste haulers focused on different client groups, more than fifty waste processors working with specific waste streams, stakeholders that store waste in landfills, companies that use or could use recycled materials, and overarching stakeholders such as the city and county.

The large number of influential and affected stakeholders is one of the main challenges the city faces in achieving circularity. As there is no one party with central oversight over the entire waste system in Charlotte, it makes it difficult to sketch a complete picture. The city and the county have access to the most complete data on households and small businesses, but as they are responsible for different parts of the waste system, both have gaps in their knowledge. Additionally, data is missing for a large share of the waste system in Charlotte as it bypasses both the city and the county when it goes from private companies to private haulers and processors.

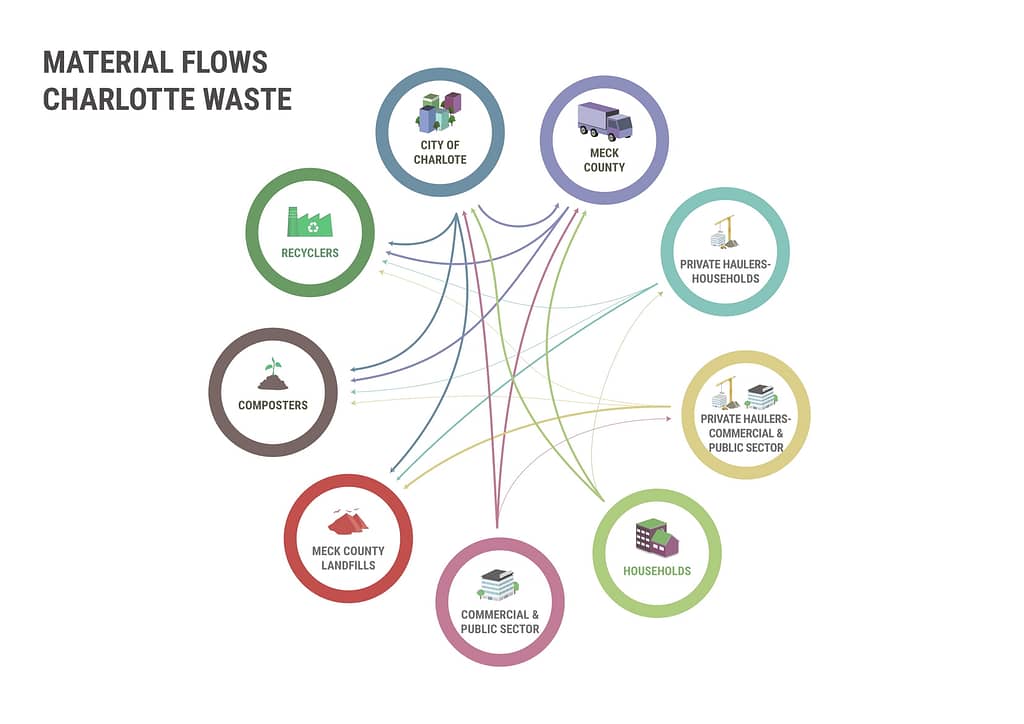

Figure 6 shows the material flows between different stakeholder groups in Charlotte. Thicker lines represent the wastel flows for which the city or county have information, while the other lines are where there is a lack of central oversight on what is happening in the waste system.

Beyond material and information flows between stakeholders in Charlotte, there are important financial flows to consider, including tipping fees, disposal taxes, special taxes (such as tire taxes or white goods taxes), revenues from recyclables, commercial service costs, etc. The structure of these financial flows is key, as it will determine which stakeholders support or are opposed to certain circularity measures.

For example, the owner of a landfill would presumably be opposed to any measure which reduce the waste to landfill without also resulting in a commensurate benefit in some other way. In this way, we need to take the position and desires of influential stakeholders into account to ensure strategies are feasible. In addition to direct opposition or support of specific measures, stakeholders may see circularity strategies as a way to position themselves in a competitive market. Waste haulers, for example, who compete for contracts, have a strong incentive to support measures which help their position.

One of the most complicated challenges around aligning interests and finding a strategy that works for all is the dynamic between the city and the county. Waste and recycling from households and some small businesses is collected by the City of Charlotte. However, due to a solid waste interlocal agreement with Mecklenburg County (currently in place until 2028), the county is responsible for this waste from this point on.

Outside of the direct financial flows between stakeholders, there are indirect economic issues which affect stakeholders in the region. For the areas in Charlotte where poverty is a major struggle, ensuring that a shift to circularity can provide a means for reducing poverty through workforce development and job opportunities is a prerequisite for adoption. At the same time, the means for achieving circularity should fit within the cultural and social structure of different communities and address additional challenges they face.

Finally, activities of other stakeholders (for example in the market or in policy) outside of the scope of Charlotte can have a large impact on how the waste system of the city functions. One example is China’s decision to limit the import of recyclables to those of a high quality, due to environmental and health reasons. In particular, household plastic wastes, unsorted paper, and some textile wastes will no longer be accepted (Prisco, 2017), which poses a challenge as China is the main importer of plastic wastes (Velis, 2014).

Chinese policy on materials accepted and the quality of recyclates will have a large impact on global markets for recyclables and is expected to have a large negative impact on United States recycling businesses, threatening thousands of jobs (Rosengren, 2017). In some cities in the United States, this ban has already resulted in the refusal of certain types of plastics (van Fleet, 2017). The effect of China as an external stakeholder could affect the feasibility of recycling options, provide an incentive to reduce plastic waste production, or present a barrier for preventing plastic wastes to landfill.

Understanding what happens with waste in Charlotte