The average U.S. citizen consumes 800 beverages packaged in disposable containers each year. Despite current recycling efforts, the majority of these 200+ billion containers end up in landfills. A new report explores the potential for circular beverage packaging in the United States.

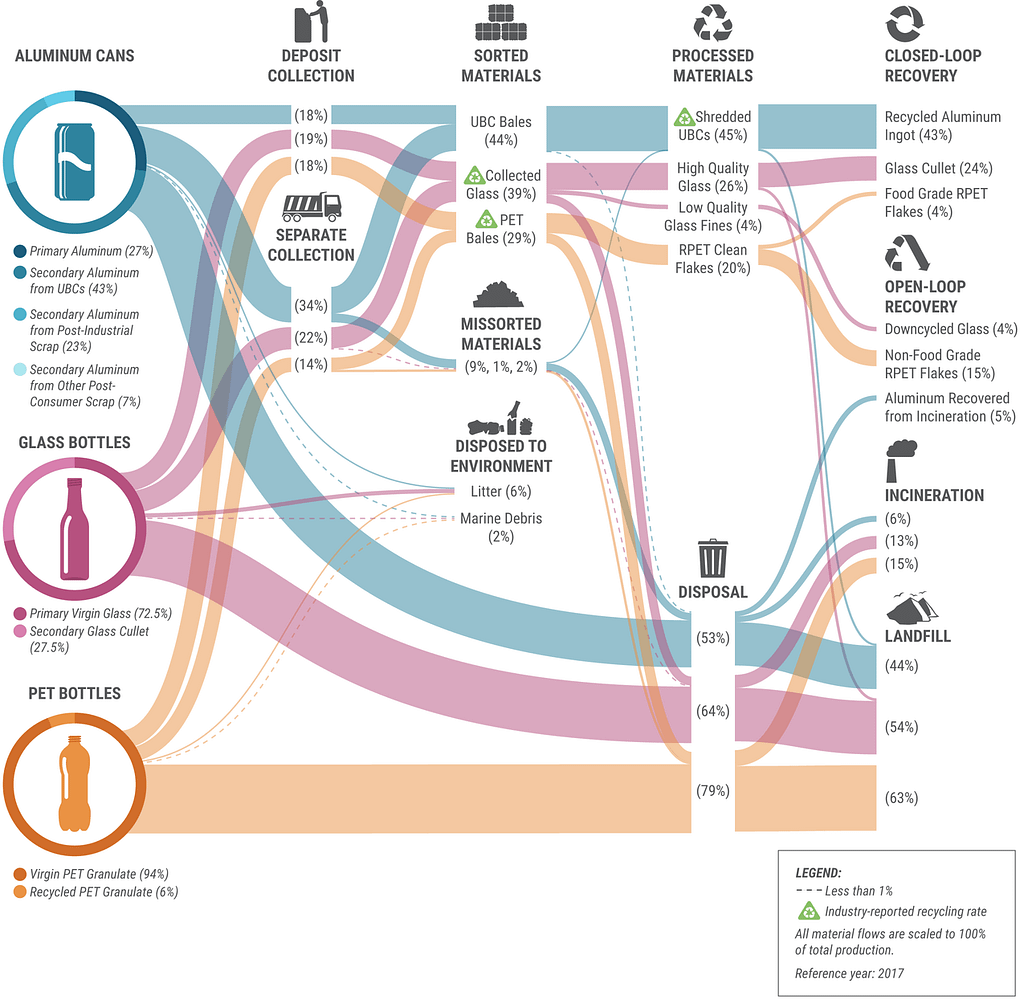

The report Recycling Unpacked: Assessing the Circular Potential of Beverage Containers in the United States assesses three U.S. beverage packaging types – aluminum cans, glass bottles, and plastic PET bottles – and finds aluminum cans currently have the highest circular performance. In today’s U.S. recycling system, more than 80 percent of beverage cans collected for recycling are recovered and turned back into new beverage containers, compared with 59 percent of glass bottles and only 13 percent of plastic PET bottles.

The analysis, carried out by Metabolic as part of a study commissioned by the Can Manufacturers Institute (CMI), explores the circular potential for each packaging type under current and future scenarios, considering how product design and recycling infrastructure influence the quality and quantity of material recovered over multiple recycling loops.

To improve the circular performance of all packaging types and move towards a fully circular beverage packaging sector in the United States, the report outlines a tailored approach for each material type.

Aluminum can recycling is a leverage point

“Aluminum cans are unique in that they were designed with recycling in mind and that is a large part of why the aluminum can is the most recycled beverage container in the United States and the world,” said CMI Vice President of Sustainability Scott Breen. “Since metal, such as aluminum, recycles forever, and we already recycle aluminum cans at scale in the United States with 5 million aluminum cans recycled every hour, there is the potential for essentially all of the aluminum in beverage cans to be recycled multiple times, generating significant environmental and economic benefits.”

But to achieve a truly circular system, recycling collection rates must be greatly improved. Of the around 90 billion aluminum cans used in the United States each year, only around half are recycled. The other half end up in landfills.

The study forecasts the potential impact if those landfilled aluminum cans were recycled instead and achieved their full circular potential. Based on a material flow analysis and dynamic model for three future scenarios – 100-percent collection, 100-percent sortation and a national deposit system – the report finds that, compared to a 2020 baseline, reaching a 100-percent collection rate for used beverage cans has the potential to save an additional 6 million metric tons of carbon dioxide equivalent (CO2e) each year – the equivalent of the annual CO2e emissions from electricity used in over 1 million U.S. homes.

The study also illustrates the impact that comes with the aluminum can’s ability to be recycled multiple times. One aluminum can recycled over and over again has the potential to displace up to 15 cans’ worth of material over 40 recycling loops.

The production of virgin aluminum carries significant environmental impacts, which makes the use of recycled aluminum in beverage can production an industry imperative.

Tailored recommendations for each packaging type

The study’s outcomes for glass and PET plastic are quite different. Glass bottles collected in single-stream recycling systems are often downcycled for low-value applications such as in construction as an aggregate, or sent to landfill. And the current glass recycling process is almost as energy-intensive as producing virgin glass, so the report recommends focusing on reuse to reach meaningful circular potential. Glass bottles can be washed and refilled up to 25 times before needing to be recycled, which displaces the need to harvest valuable raw materials such as silica and soda ash for glass production.

PET plastic poses challenges for circularity as its material properties degrade when it is recycled. Achieving food-grade quality recycled PET is complex, hence the low percentage (13%) of collected PET that is currently converted back into new beverage bottles. To improve circularity for PET plastic bottles, the report recommends PET bottle producers advocate for bottle deposit systems, while exploring energy-efficient chemical recycling opportunities for material that can no longer be mechanically recycled.

The expansion of deposit return systems across the United States would greatly improve the circular performance of all three packaging types.

A call to action

To unlock the full circular potential of all materials analyzed, the report shares a call to action with the U.S. beverage packaging sector, underscoring the need for a systemic transition bolstered by coordinated action from all stakeholders across the value chain:

- Business models and collection incentives need to be aligned for each material type (e.g., glass should be driven toward refillable systems; aluminum cans toward increased recycling; and plastic towards deposit return systems).

- Collection rates for all three materials must be dramatically increased. This can happen by increasing curbside collection while advocating for deposit return systems – such as the bottle bill system – to be rolled out across the United States.

- While bottle bill deposit systems are being set up, PET producers should invest in chemical recycling technologies and critically assess the life cycle impacts of these processes, shifting towards renewable sources of energy if impacts are high.

- The aluminum industry should explore new recycling technologies that separate the can top from the can body in the recycling process. This would help maintain aluminum alloy properties over multiple recycling loops and raise the recycled content ceiling for aluminum cans.

- Material recovery facilities should invest in additional eddy current technologies, which magnetize and separate aluminum from other material types, to ensure all aluminum cans that enter the recycling system can be sorted correctly for recycling.

- Decision-makers should monitor progress toward circularity not just by measuring and acting upon recycling rates, but also by evaluating annual rates of material displacement, measuring whether materials collected for recycling are used in open-loop or closed-loop systems, determining whether materials are recycled into products that can easily be recycled again, monitoring the material and energy efficiency of the recycling process, and quantifying the impact of interventions from a systems-oriented life cycle perspective.

- Finally, beverage producers should explore reducing the need for beverage packaging altogether by investing in drink concentrates, home-based beverage systems, and other solutions that meet consumers’ needs while reducing overall packaging production.

“It’s important to keep in mind that a product only achieves high circular performance in a properly functioning circular system,” said James Souder, lead author and sustainability consultant at Metabolic. “All materials could be handled in a non-circular way. So it’s critical that we look not only at each material’s properties, but also at the systemic factors that influence how each material is collected, processed and reintegrated into new products, while finding key points to shift the system towards a more circular and sustainable future.”

Read the full report here.