The global shift away from fossil fuels presents us with an opportunity. In redesigning systems to mitigate climate change, we have a chance to rethink the way we interact with natural resources as a whole, and prioritize systems that improve the quality of human life.

The study Metal Demand for Electric Vehicles developed by Copper8, University of Leiden, and Metabolic, focuses on rethinking mobility. In the race towards a carbon-free economy, electric vehicles offer a promising solution for cleaner, more efficient passenger transport that can be powered by renewable energy. As a result, this is where governments and automotive producers are focusing their attention.

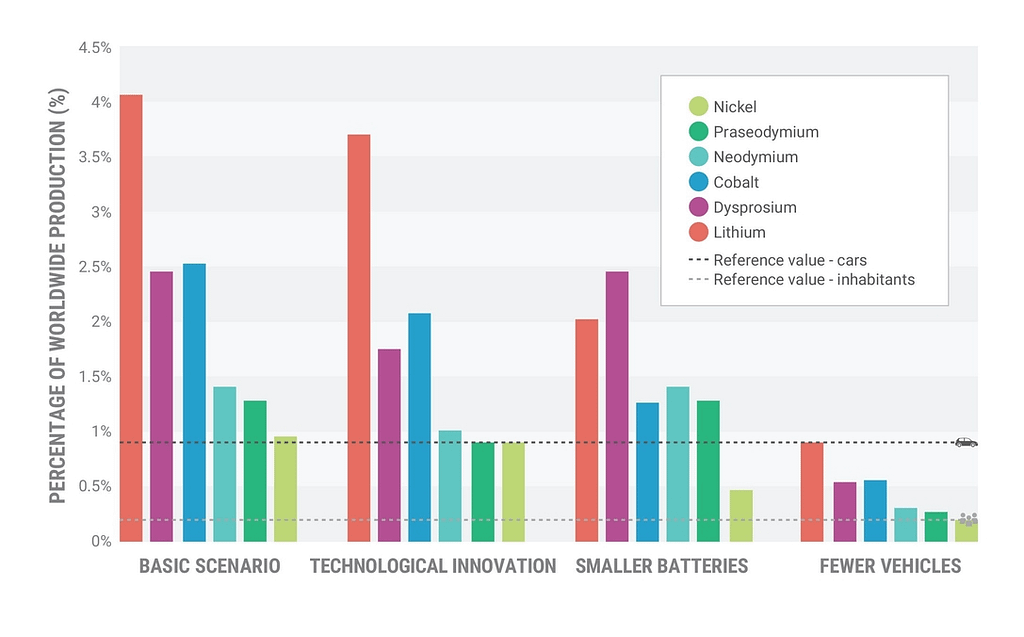

However, research from the Netherlands reveals limitations in the supply of critical metals needed to produce efficient and high-performing electric vehicles. Production of some of these metals, such as nickel, praseodymium, neodymium, cobalt, dysprosium and lithium, would have to scale threefold in the coming ten years to meet projected global electric vehicle demand.

Production chains for critical metals are long and complex. Scaling up production requires significant investment, and investments need to start today in order to have a new mine in operation ten years from now. Critical metals are also used as leverage to exert geopolitical influence. Moreover, mining activities are sometimes related to human rights violations and frequently cause significant environmental damage.

As we design low-carbon passenger transport with these complex metal supply chains in mind, we must understand where large shifts create new dependencies and navigate potential trade-offs. This may mean creating entirely new systems that offer the most future-proof pathway.

A sustainable, fair, and resilient transport sector involves reducing our dependence on privately owned vehicles, through promotion of new mobility concepts that make more effective use of existing vehicles, and improved public transport infrastructure. Also critical is the development of a circular economy within the industry, enabling maximum resource efficiency.

The study provides recommendations for a future-proof mobility sector based on the Dutch and European settings, however many of these can be transferred and applied to other contexts. It is the second in a series of studies on the metal demand for our new, carbon-free economy, following an earlier study on the critical metal demand for solar panels and wind turbines. The aim of these studies is to understand the new dependencies arising from a carbon-free economy, and what we can do to move, rapidly and safely, towards this new economy with both societal needs and critical raw materials in mind.

Read the report here.