Recycling Unpacked

Assessing the Circular Potential of Beverage Containers in the United States

Metabolic and the Can Manufacturers Institute explored the potential for a fully circular beverage packaging sector in the United States — focusing on aluminum cans, glass bottles, and plastic PET bottles.

- Client: Can Manufacturers Institute

- Date: October 2020

Reducing waste and impacts from beverage packaging

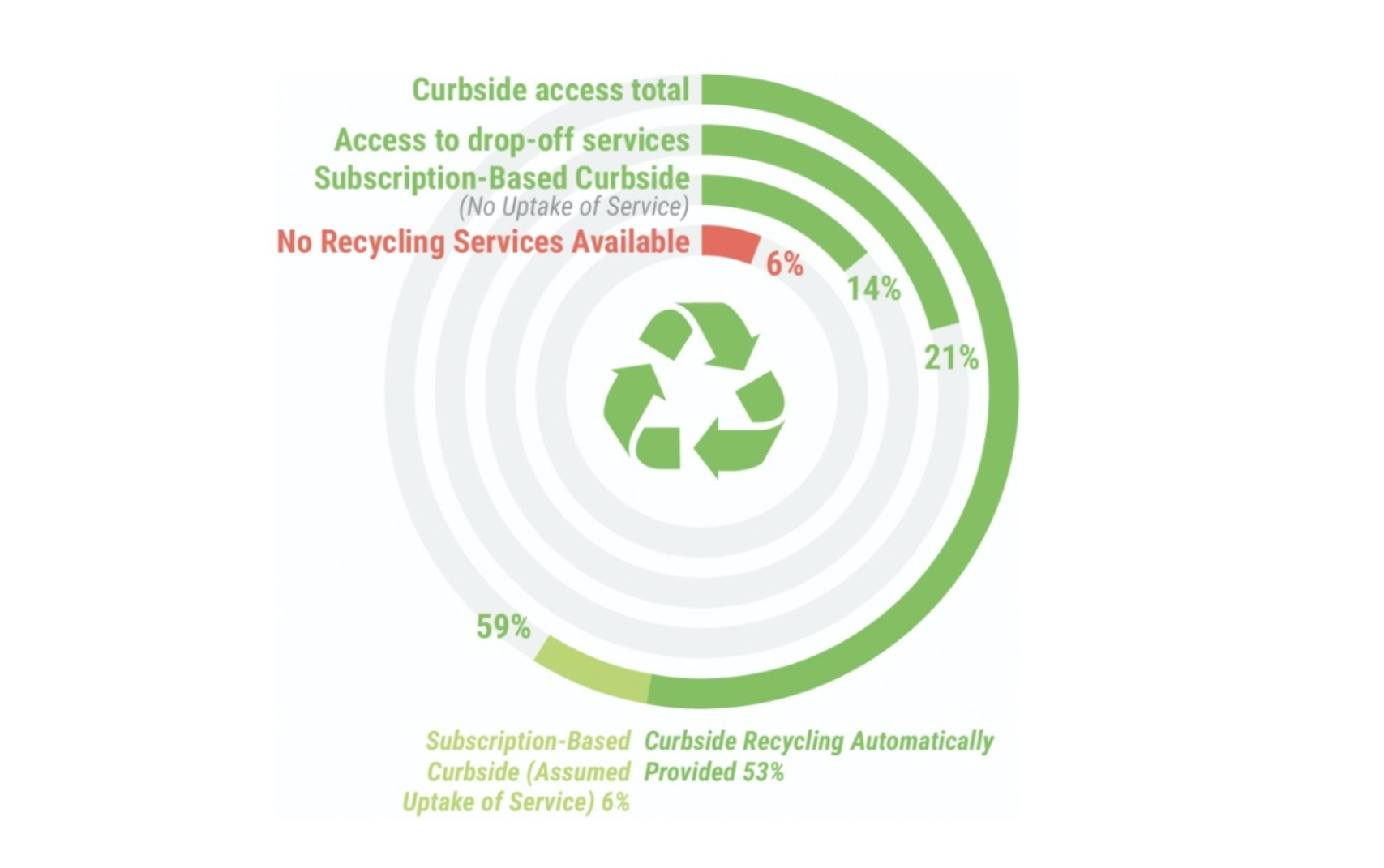

The average U.S. citizen consumes 800 beverages packaged in disposable containers each year. While over half of U.S. households have access to curbside recycling services, the majority of these 200+ billion containers end up in landfills, resulting in significant economic and environmental losses.

The Can Manufacturers Institute commissioned Metabolic to analyse the circular potential of three beverage packaging types: aluminum cans, glass bottles and plastic bottles, tracking their respective journeys through the U.S. recycling system, and calculating what is needed to make these product systems fully circular.

Circular potential in the U.S. recycling system

Our analysis explored the circular potential for each packaging type – aluminum cans, glass bottles and PET bottles – under current and future scenarios. To understand how product design and recycling infrastructure influence the quality and quantity of material recovered over multiple recycling loops, we focused on four areas:

- Design: the way a product is designed, and the properties of the materials it is made of, greatly influence whether the product is destined for continuous circulation or eventual disposal.

- Production: we assessed the life cycle impacts of producing each material, to understand whether material recovery will result in significant reductions in energy, water, and GHG emission impacts across the three packaging types.

- U.S. Recycling System Assessment: mapping how each material is currently being collected, processed, and recovered in the current U.S. recycling system in a material flow analysis, highlighting the key system leverage points that inhibit reaching a circular state.

- Intervention scenarios: Finally, we modelled the potential for circularity by improving the U.S. recycling system through three hypothetical scenarios: increased collection, improved sorting technologies, and implementing a national bottle deposit system.

Aluminum cans are a leverage point

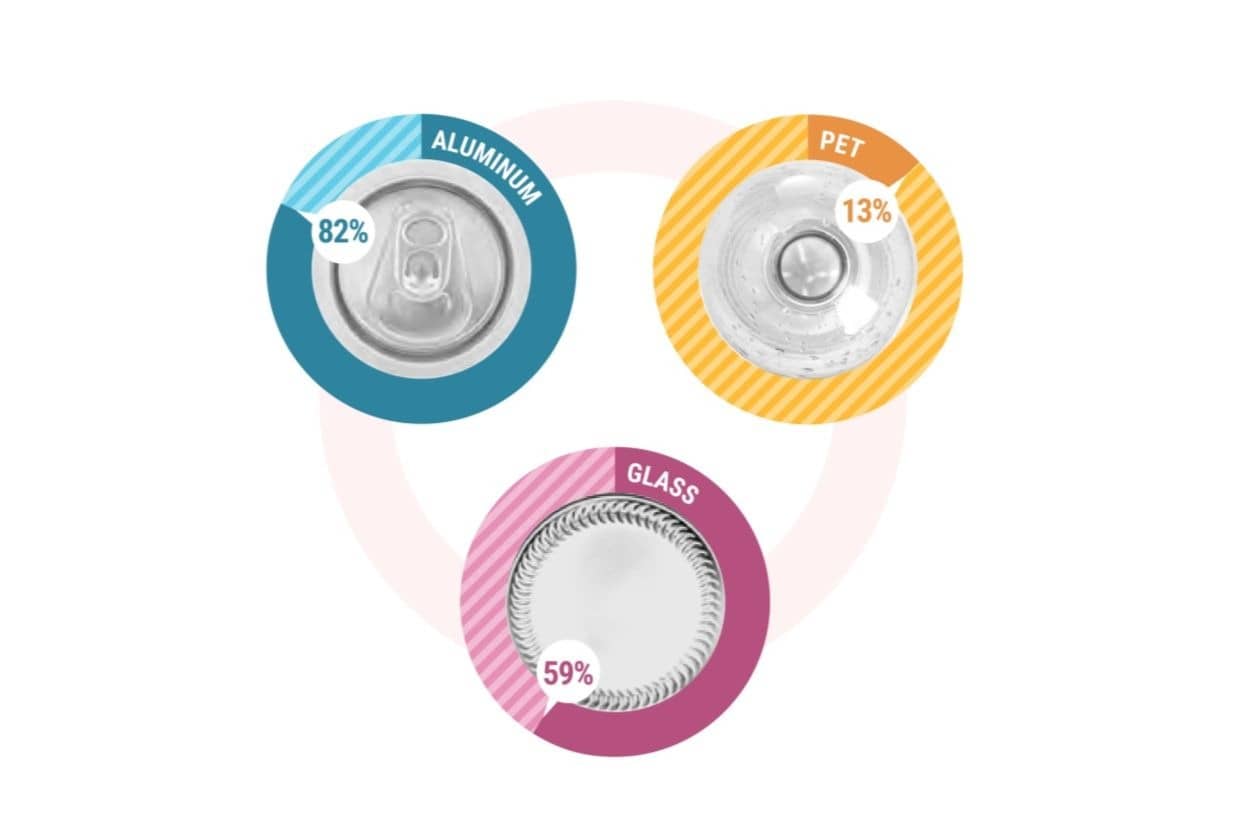

Of the three packaging types investigated, aluminum cans currently perform highest in terms of circularity. In today’s U.S. system, more than 80 percent of beverage cans collected for recycling are recovered and turned back into new beverage containers, compared with 59 percent of glass bottles and 13 percent of plastic PET bottles.

Aluminum cans also show the highest impact reduction potential under the three modeled scenarios, considering both open- and closed-loop material recovery. According to our model, collecting and recycling 100 percent of aluminum cans compared to the 2020 baseline has the potential to save an additional 6 million metric tons of carbon dioxide equivalent (CO2e) each year – the same as the annual CO2e emissions from electricity used in over 1 million U.S. homes.

The report provides tailored recommendations to increase the circularity of each packaging type:

- While aluminum cans have high circular potential, recycling collection rates must be improved, most effectively through deposit return systems.

- For glass bottles, reuse should be prioritized over recycling, directed used glass bottles towards localized reuse systems to maximize impact reduction potential.

- PET bottle producers should support bottle deposit systems, while exploring energy-efficient chemical recycling opportunities for material that can no longer be mechanically recycled.

Rolling out bottle deposit collection systems across the United States would greatly improve the circular performance of all three packaging types.

"Since metal, such as aluminum, recycles forever, and we already recycle aluminum cans at scale in the United States with 5 million aluminum cans recycled every hour, there is the potential for essentially all of the aluminum in beverage cans to be recycled multiple times, generating significant environmental and economic benefits."

Scott Breen, CMI Vice President of Sustainability

"It’s important to keep in mind that a product only achieves high circular performance in a properly functioning circular system. All materials could be handled in a non-circular way. So it’s critical that we look not only at each material’s properties, but also at the systemic factors that influence how each material is collected, processed and reintegrated into new products, while finding key points to shift the system towards a more circular and sustainable future."

James Souder, lead author and sustainability consultant at Metabolic