During Circular City Week New York, Metabolic hosted the webinar ‘Recycling Unpacked: Maximizing Circularity in U.S. Beverage Packaging.’ Our consultant James Souder joined speakers from across the supply chain to discuss the challenges to creating truly circular packaging streams, including design, infrastructure, and local policies.

Everyday, residents of Boulder, Colorado call recycler Eco-Cycle asking the same question: “Is this recyclable?”

“When we say no, they get mad,” said Kate Bailey, policy and research director of the non-profit Eco-Cycle, which started one of the first curbside recycling programs in the U.S. “They ask, ‘Don’t you talk to the packagers and tell them it should be?’ And we say, ‘No.’ ”

For decades, recyclers and packagers have operated independently from each other, which has prevented circular systems from forming. However, in the past two years, Bailey said she has seen conversations open up throughout the supply chain. “That’s huge,” Bailey said during the ‘Recycling Unpacked: Maximizing Circularity in U.S. Beverage Packaging’ webinar held during Circular City Week New York in March 2021.

For example, if the highest and best use for glass is to reuse bottles as bottles, rather than to re-manufacture into other materials by breaking down the glass into “cullet,” then bottles would need to be adequately sorted, which would require investment in secondary recovery facilities, and the preferred color of glass should be produced up front. This can only be done with conversations throughout the supply chain.

Obstacles like these abound throughout the supply chain, said Elizabeth Balkan, director of North America for Reloop, an international non-profit organization that brings together industry, government and NGOs that share a vision of a thriving global circular economy. These challenges include package design, missing infrastructure required for collection and processing, market conditions and commodity pricing, and the vast differences in the recycling systems and regulatory policies in place. Policy advocacy for closed loop packaging is where Reloop focuses much of its work.

Mandatory recycling policies would be an effective way to improve circularity, said Bridget Anderson, deputy commissioner for recycling and sustainability at the New York City Department of Sanitation. The city has had mandatory recycling in place since 1989 for beverage containers in the residential and commercial sector. However, of the items not returned through deposit schemes, only about 42% is captured in recycling bins.

With the introduction of the United State’s Break Free from Plastic Pollution Act, Balkan sees new hope about a national bottle collection refund. The bill calls for a 10-cent minimum refund regardless of material.

“We see from Europe and from elsewhere around the world that effective best-in-class return systems can easily achieve a 90% collection rate for beverage containers,” Balkan said. “So this is not fantasy, this is reality.” Reloop is still analyzing the potential impact a national bill would have, but by looking at data from five states with bottle return systems, Balkan said it would be massive. The impact would extend to greenhouse gas savings, reduced litter, increased tax revenues and job creation, and improved quality of life, she said.

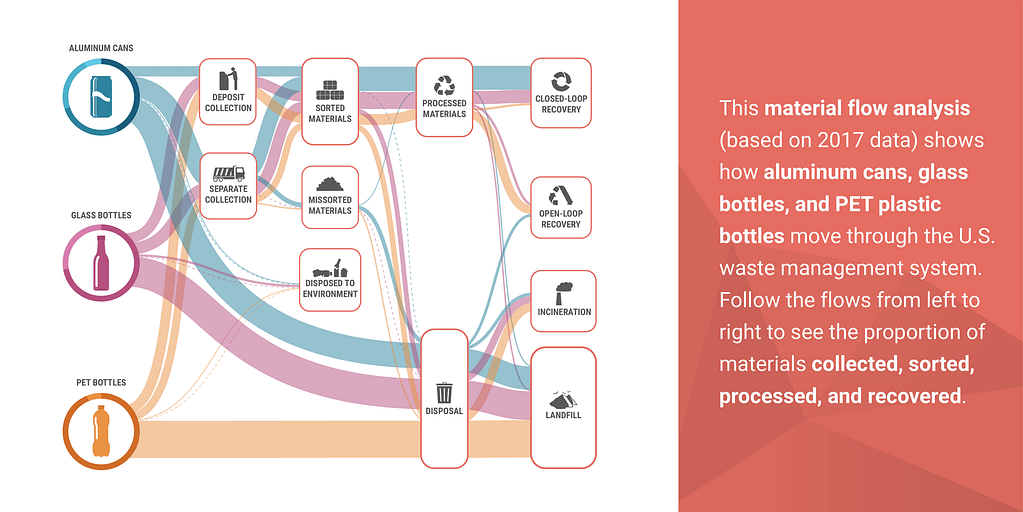

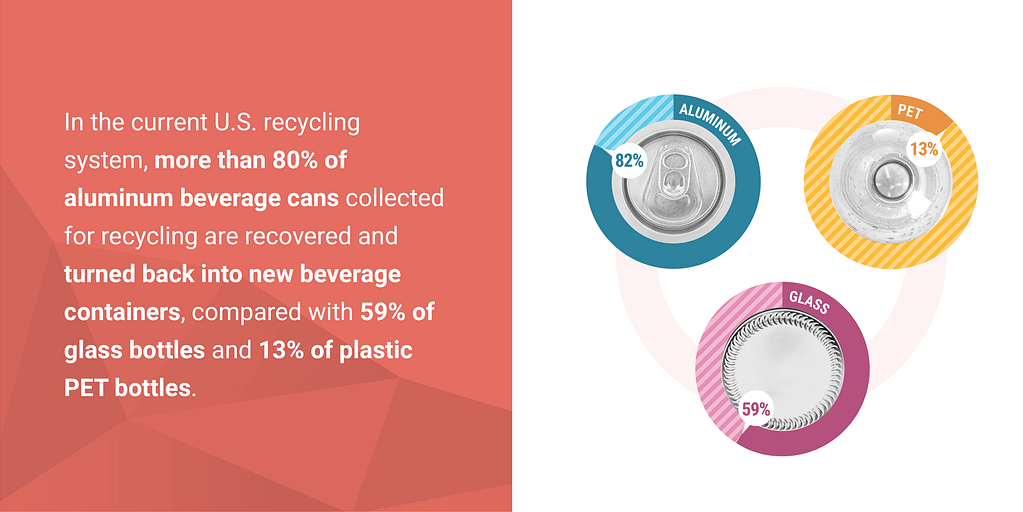

A successful recycling system preserves the embodied value in products and materials, and creates a strong and reliable source of secondary materials that can compete with primary resource production, said James Souder, who leads the Products & Services team at Metabolic. Currently in the United States, more than half of all aluminum cans, glass bottles and PET bottles end up in the landfill or incinerated, according to a material analysis flow on beverage containers conducted for the Recycling Unpacked report released last year. For PET bottles, that figure is as high as 79%.

“We’re not only facing a waste management problem — we’re facing a waste production problem,” said Souder, who co-authored the report. “If we design our materials and products to be waste, then of course we are going to treat them that way. We instead need to start designing and thinking about our products as resource banks, something that can live through multiple cycles.”

Bottle deposit collection systems in the States would improve the circular performance of different types of bottles. To improve the recycling rates of aluminum cans, for example, incentives through deposit return systems would be most effective, Souder said. By contrast, the most circular potential for glass is localized reuse systems, such as having bottles refilled at your store, because breaking, melting, recreating, and transporting glass bottles is quite energy-intensive. Finally, new opportunities for energy-efficient chemical recycling for PET bottles could replace mechanical recycling processes.

Bottle deposits can also be especially effective at driving consumer participation, Bailey said. “We can build the best recycling system, we can create the markets, but at the end of the day, we are relying on the consumer to put it in the bin and bring it back to the store,” she said. Consumers need access and incentivization, she said, not just education.

Nestle Waters, one of the largest non-alcoholic beverage companies in the U.S. which produces, sells, and distributes six bottled water brands, is also communicating more closely with recyclers to better understand how packaging interacts with their recycling streams, and how to improve that performance. “With that kind of design for recyclability at the front end, it allows us to have more confidence that the packaging that we’re putting into the system, once it’s recycled, it has a higher degree of probability of us being able to use it to put it back into another bottle for that circular economy,” said Peter DePasquale, who leads government and regulatory affairs in North America.

Historically, using post-consumer recycled content has not been a viable long-term option for companies, DePasquale said, because of the higher cost of recycled materials compared to virgin materials. Policy intervention on both the demand side and supply side could help with consistency in the marketplace. DePasquale also hopes consumers are able to make better buying decisions in regards to circularity if they know whether products are made from recycled or virgin materials.

Improving supply chain communications along with consumer education and knowledge, in addition to pursuing programs like bottle deposits and collection systems, could all go far in improving recycling of beverage packaging. And then, perhaps recyclers like Eco-Cycle will be able to say ‘Yes’ when customers ask if an item is recyclable and if packagers and recyclers are working together.